INMERBOT

Research in immersive and sensory technologies for collaborative industrial robotic inspection environments

Environments requiring inspection and maintenance tasks are often hazardous or difficult to access for operators.

Mobile robotics allows the intelligent automation of some of the operations related to the maintenance and inspection of these areas, saving people from these repetitive, risky and tedious tasks, and minimising possible errors.

What are these environments and what kind of operations are they intended to address?

The nuclear industry (reactor maintenance), chemical (remote handling of hazardous or toxic substances), military (detection, handling and dismantling of explosive charges), humanitarian demining, space (explorations carried out on the moon and Mars, also in space shuttles), mining (excavations, handling of explosive charges in mines and tunnels), among others.

INMERBOT proposes research that extends immersive and sensory technologies to improve robotic inspection in industrial and non-industrial environments.

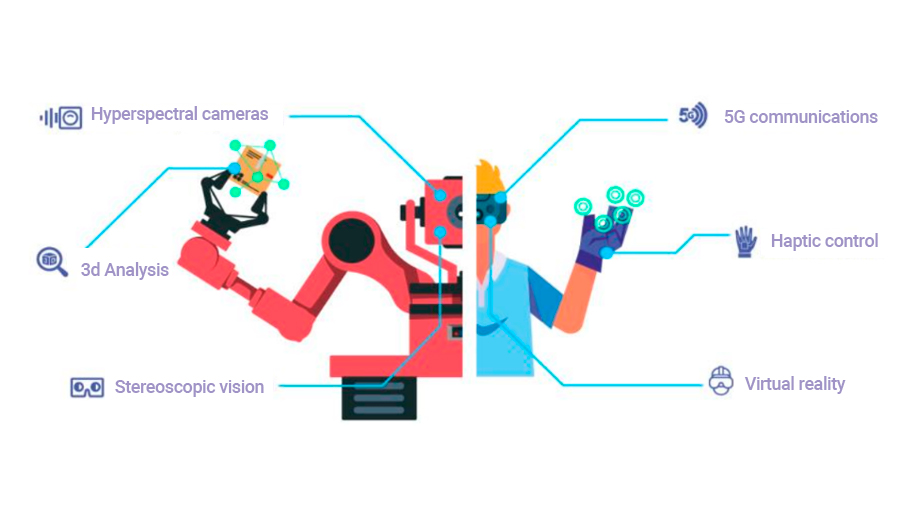

To advance the knowledge of teleoperation and management of multi-robotic systems in highly immersive environments for inspection and maintenance applications, research is needed in haptic technologies, robotics or environmental analysis using diverse sensors, as well as research in the use of artificial intelligence for mobility, defect detection and reconstruction of the environment from sensor data and vision cameras.

There are currently significant limitations to efficient human-robot and robot-robot collaboration in facility inspection and maintenance environments:

● Lack of information that operators can obtain and process. This information makes it possible for them to efficiently control a robot remotely. It is necessary for the end-user to have access to:

-

- Real-world visual odometry, positioning and environment.

- Map data.

- Any laser range finder, probe or other sensor.

- Data used by the robot for obstacle detection and location.

● Robots are commanded by an operator through a master device from a safe environment. The force feedback received by the host device has normally been created from the positional error between the main operator’s movement and the teleoperated device and haptic systems. The lack of synergy between the parts and the information part of the environment is a point that limits the options for effective teleoperation.

● Robot-robot collaboration does not exist today and they have to be commanded individually.

GENERAL OBJECTIVES OF IMMERBOT

- To investigate collaborative dynamic robot systems that, unlike classical industrial robots, can operate in unstructured, fully dynamic and partially observable environments, enabling a new range of disruptive services and functionalities for semi-autonomous and autonomous inspection in heterogeneous environments (terrestrial and aquatic). The aim of these services is to improve conditions.

- Research immersive environments for industrial inspection in unattended facilities (renewable energy generation plants, electrical substations, chemical treatment plants), and specifically in sectors that represent risks and complex and high-cost inspections (economic, personnel, time), facilitating the transformation and digitisation of strategic sectors in Spanish industry.

- Research into new sensory technologies for inclusion in robot-robot and human-robot ecosystems with advanced perception capabilities (immersive and haptic technologies, AI, environmental reconstruction, sensory capabilities, communications architectures) in order to increase and extend human inspection capabilities and promote equipment failure prediction systems, decision support, the sustainability of inspection operations, the efficient use of industrial resources and efficiency throughout the value chain.

- Research on efficient robotic inspection systems (mission resolution, task planning) that facilitate the reduction of the operating cost of industrial plants, so that they can operate unattended, promoting energy efficiency and sustainability.

ROBOTNIK IN THE PROJECT

Robotnik is in charge of designing, developing and implementing the RB-VOGUI+ mobile robot, an autonomous robotic solution capable of performing inspection and maintenance tasks.

Based on the identification of the operational requirements within the project and Robotnik’s experience in adapted robotic solutions:

● New sensorisation systems applicable to robotic tools/grippers will be investigated in a way that can be governed by haptic glove.

● Robotic systems will be designed for the movement of a stereoscopic camera.

● Distributed robotics scenarios potentially present in robotic inspection services will be modeled.

● New algorithms will be investigated to solve the problems of multi-robotic systems in inspection services, in particular search/coverage, motion planning and formation control.

● They will be validated and demonstrated at subsystem level and in industrial reference environments.

More projects