ROBOCOMP

Robotics & Automation for Composite Components Manufacturing

The ROBOCOMP project is part of smart and advanced manufacturing and digitization in the aeronautical sector under a sustainable point of view. It proposes the investigation of automation and robotics technologies to accelerate and optimize the manufacturing processes of various fundamental components for aircraft.

The general objective of ROBOCOMP, a project funded by the CDTI, is to investigate technologies aimed at reducing emissions in the manufacture of composite materials through research activities based on the automation and robotization of processes that, today, are still manual in the manufacture of composite materials.

This project will enable a fully sensorized and interconnected E2E automation concept that will be focused on the following components: multi-spar stabilizer, underwing skin and rear fuselage section 6; in order to close the gap between current technologies and manufacturing processes (manufacturing rates of 10 aircraft / month) and future fully automated manufacturing (manufacturing rates of 100 aircraft / month).

To achieve the general objective, the following specific objectives are proposed:

- Prepare the technology to increase the manufacturing rates of the main components manufactured in Spain through the automation of all its processes.

- Reduce the unit cost of manufacturing aerostructures thanks to the reduction in manufacturing hours. This reduction will be achieved to a large extent thanks to the optimization of the industrial manufacturing line by automating the manual tasks addressed in ROBOCOMP.

- Advance towards more sustainable carbon fiber manufacturing processes.

- Availability of new automation technologies for manufacturing throughout the value chain of the Spanish industrial ecosystem.

- Have interconnected manufacturing means (factory 4.0) that provide real-time data on manufacturing processes.

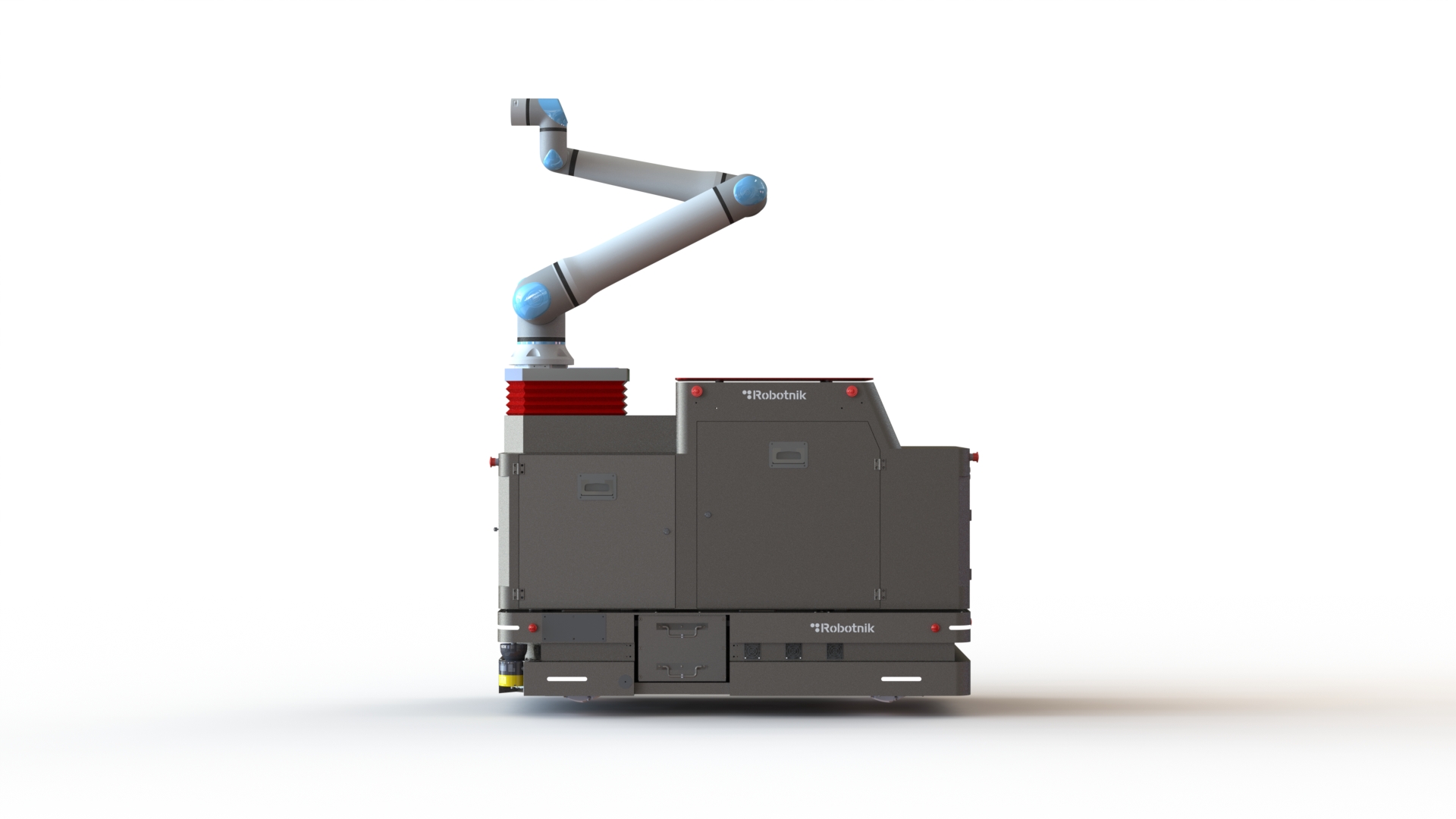

ROBOTNIK IN THE PROJECT

The general objective of Robotnik is to research and develop the general purpose modular mobile manipulator robot RB-ROBOUT+, suitable for fully autonomous manufacturing processes and operations on large parts. Robotnik’s specific objectives include R&D of the mechatronics of the extended range and load mobile manipulator, R&D of standardized tool systems at the connection and data level, as well as R&D of a power supply solution for battery in non-stop mode.

At the architectural level, Robotnik is going to design robot positioning solutions and repositioning with respect to the part, enabling operations on large parts without the need for expensive high-precision absolute location systems, investigate cloud/edge technologies for computing download in the cloud, data sharing and cybersecurity support for industrial use, researching technologies that allow the connection, monitoring, supervision and interface of robots in the cloud/edge with the cybersecurity conditions required for industrial use.

View more projects