TIRANT

Improvement and optimization of the electric arc machining process

One advantage of the introduction of robotics in certain sectors is the possibility of such robots could execute dangerous, repetitive and low value tasks.

One task where these factors are located is in the metallic coating. Robotnik’s contribution, along with Dominguis Group, is Tirant 3 robot, designed to work in nuclear power plant piping systems.

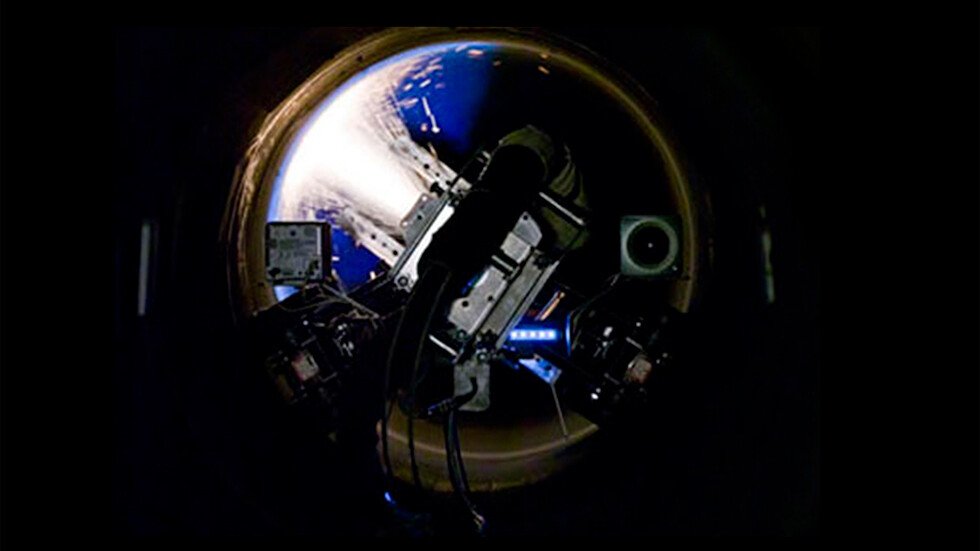

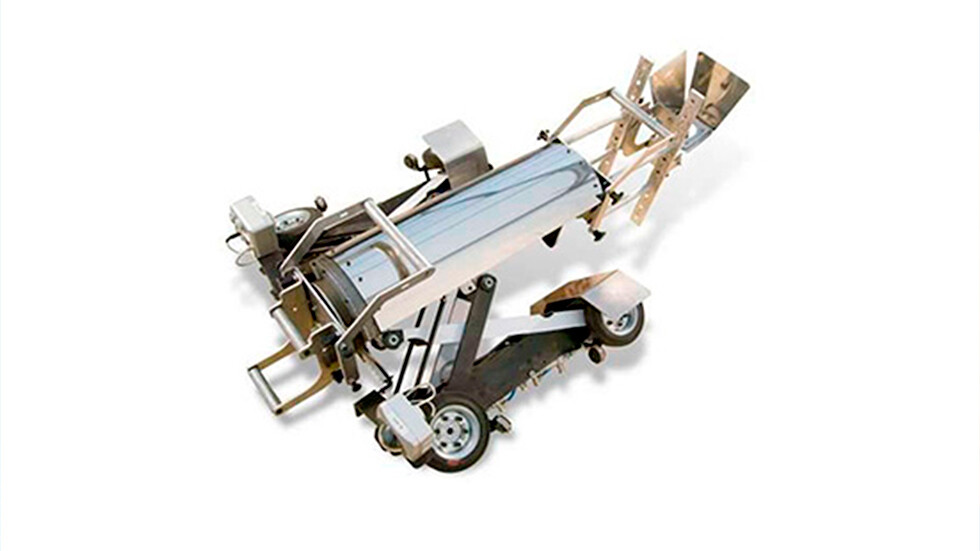

The robot developed by Robotnik aims to perform metallization tasks within the pipes of a nuclear plant. The platform can access to pipe diameters between 30-42 inches and its speed is between 20cm/h and 10 m/h. The robot has an anti-roll system and withstands temperatures up to 100 ° C.

The robot, that can operate autonomously or manually, is fitted with a spray-gun for metal on its last effector of the arm, working in a circular motion with a fixed distance from the tube.

It is a system that automates a repetitive and arduous task, which was being done manually by an operator. Tirant III robot has been designed by Robotnik in collaboration with Dominguis Group, who has performed metallization services in nuclear plants with them, obtaining excellent results.

More projects

TIRANT