The uses of robotics are consolidated in many professional sectors with an unprecedented increase in Europe of 24% in the last year. Specifically, statistics point to a growth in global demand for autonomous mobile robotics of 40% per year, according to IFR (International Federation of Robotics) predictions. Currently, there are more than 5,000 autonomous mobile robots from Robotnik working with people and for people around the world, powering different industries globally.

After 20 years in the robotics business, Robotnik’s experience is that all investment in robotics and autonomous mobile handling comes back to the benefit of the end user, both in terms of economics and productivity.

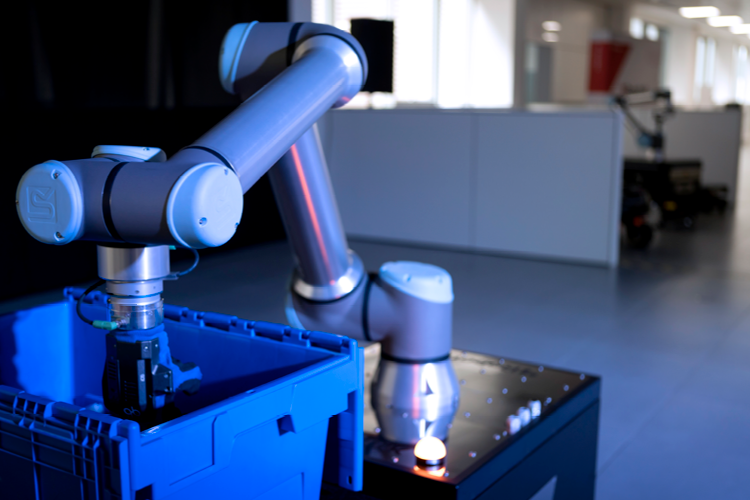

Collaborative robotics is the tool for companies to evolve in a competitive, intelligent and constant way. Therefore, the use of robotics is no longer only part of the strategy of large multinationals but also of SMEs, as it is flexible, scalable and adaptable to the needs of any type of company, however small it may be.

Uses of robotics Nowadays, autonomous mobile robotics has changed the automation landscape, especially in collaborative spaces where humans and robots work together. Industries are no longer just looking to automate, but rather to use intelligent automation to optimise both production and profitability. This is borne out by the success stories of the last twenty years. Here you will find 9 real uses of robotics framed in the three verticals in which Robotnik is at the forefront: Mobile Handling, Inspection and Transport. In this list you can consult the uses of robotics in different fields in which autonomous mobile robots are already being successfully employed:

5 benefits of the use of industrial robotics

Uses of mobile robotics are consolidated in Industry 4.0, so the advantages it brings to it are widely contrasted. Some of the most outstanding of these are:

- Cost-effective processes: an AMR can carry out complete work shifts, so that production runs 24 hours a day without interruption.

- Error reduction: robots are programmed to carry out a task with total precision and always in the same way, which contributes to the fact that the number of failures is practically zero.

- Safety: a collaborative robot can work safely in human work environments, becoming a working tool for the operator.

- Flexibility: For the use of robotics, the mobility of AMRs and mobile manipulators is key. This allows the robot to perform different tasks in multiple locations. In short, the robot can work wherever the company needs it.

- Automation of repetitive and tedious processes for humans, who will be able to perform higher value tasks.

How do we facilitate the use of robotics?

An intuitive and easier use of robotics.

One of Robotnik’s objectives is to facilitate the process of incorporating autonomous mobile robotics for the end user who, in most cases, does not have any connection with the robotics sector or specific knowledge (e.g. programming). Flexibility and ease of implementation have contributed to the increasing use of autonomous mobile robotics in the industrial sector. Providing end-users with user-friendly tools to control their robots is one of the keys to success.

- The Advanced User Interface: is a Robotnik’s own development which consists in a tool to control and manage the robots in an user-friendly way. It allows the end user to monitor the robot in real time or to launch missions, among other actions. In addition, it is accessible from any type of device (computer, tablet, mobile device, …).

- Free navigation. The free navigation by using lasers, means that it is not necessary a large installation or previous infrastructure to incorporate mobile robotics. Robotnik robots do not require a delimited security perimeter, but can move safely from one point to another to operate in different locations. The free navigation of AMRs is one of the major differences compared to the application of an Automated Guided Vehicle (AGV).

- Collaborative. The collaborative robotics developed and manufactured by Robotnik integrate sensors, lasers and different technologies that enable them to process data from the environment in real time and make an intelligent decision autonomously. Therefore, they can work collaboratively sharing industrial spaces with humans, ensuring safety.

- Scalable. Mobility and autonomy make these robots flexible and scalable systems both in terms of the space of action and the number of units: they can be progressively increased according to needs.

- Price. In the past, the use of robotics was exclusive to large companies, due to the high cost of implementation of robotic systems. Robotnik, despite having a process of development and manufacture of mobile robots completely in-house, has lowered the cost of sale, thus being able to reach many SMEs that previously had no access.