OASEES

Open autonomous programmable cloud apps & smart sensors

As edge computing grows in popularity, traditional infrastructure and service management platforms are becoming outdated.

To truly harness the power of edge processing, a comprehensive solution that integrates core infrastructures with intelligent devices is needed. Unfortunately, the open source management environments that currently exist are limited in scope and are not designed for private deployments.

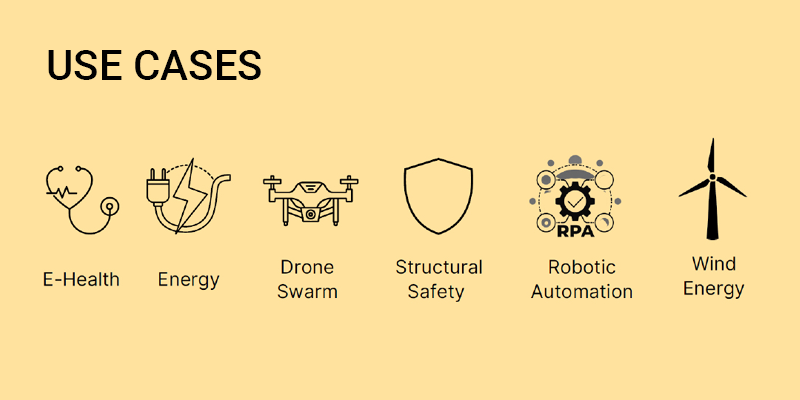

The OASEES project works to improve edge computing through Swarm, a cutting-edge open source, decentralised and secure programming framework. This innovative solution leverages the latest AI/ML accelerators, as well as FPGAs, SNNs and Quantum, while ensuring privacy through its Object ID federation process.

ROBOTNIK IN THE PROJECT

Robotnik is responsible for developing and managing the OASEES project’s fifth use case, “Collaborative robotic automation”, that focuses on implementing an automated manufacturing process for the production of furniture. The pilot aims to relieve human operators from dangerous and low added value tasks by incorporating industrial anthropomorphic robots and collaborative robots, as well as autonomous mobile robots, into the production line. The focus of this use case is on the finishing (sanding) machine, which is designed to meet the demands of medium and large companies seeking high-quality sanding and finishing operations.

To achieve this goal, the OASEES project will integrate a smart AGV system that will work with both robots and operators to sand furniture pieces. The anthropomorphic robot used in the sanding process will be equipped with torque sensors and assisted by an artificial intelligence system to adapt to the different shapes and sizes of the furniture pieces. The OASEES AI Load Balancer will monitor the status of each product, while the IoT system Maestro Connect will collect and analyze data to ensure full control of the production process. The success of the pilot will be evaluated through visual and roughness tests, as well as through a comparison of the final yield between a human and a robot sanding the same piece.

This use case has the potential to bring about a 10% increase in the OECD Job Quality Index through work environment and safety improvements, as well as a 15% increase in productivity. By incorporating advanced technologies and optimizing the manufacturing process, OASEES aims to bring about a new era of smart factories that can meet the demands of the evolving furniture market.

View more projects