ROMAN

RobMoSys adoption in the lightning system Manufacturing environment

RobMoSys aims to coordinate the whole community’s best and concerted efforts to realise a step-change towards a European ecosystem for open and sustainable industry-grade software development for robotics.

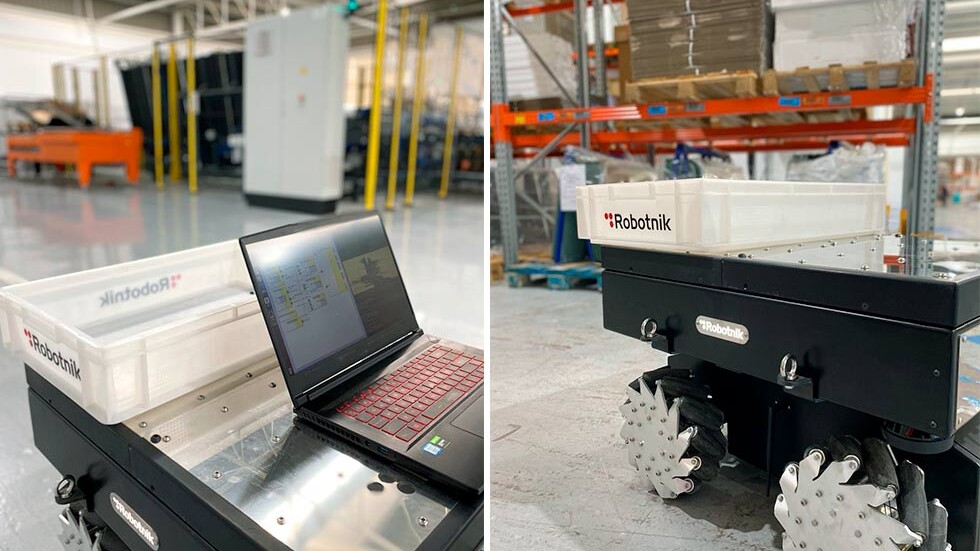

Robotnik has developed a pilot integrating the components in an existing robot. For this use case a SUMMIT-XL STEEL robot manufactured by Robotnik is used. It is a robotic platform that has a robust design and can carry up to 250 kg payload. The mobile platform has omnidirectional kinematics increasing the navigation possibilities. It is equipped with two lasers that ensure a safe and optimal navigation. The built-in router and the 8-hour battery autonomy makes it an optimal choice for industrial purposes.

The RobMoSys structure ensures a proper integration of the robot in a lighting systems manufacturing company. Different loads between 30 and 150 kg are moved continuously between machines and this is intended to be done by the robot, which can be commanded and monitored through the internal network of the company. The robot receives different positions to approach the machines and it navigates autonomously finding an optimal path and avoiding different obstacles that might appear during the trajectory.

ROBOTNIK IN THE PROJECT

The selected pilot to be adapted in a real industrial environment is the one that deals with the good transport in a company. Robotnik has been in the service robotics market since 2002 and provides industrial companies with mobile platforms that are mainly used for moving loads autonomously. This pilot will ease the integration of the robots in an industrial environment not only for the robot features but also with the rest of the systems and machines involved in the activities of the company through different IoT protocols (like OPCua or REST).

More projects