SYMPHONY

Intelligent system for operational improvement in the industry

Development of technologies for the optimization of industrial manufacturing processes. The project focuses in mobile manipulation (Robotnik), cloud software and infrastructure (Robotnik), AI for production (ITERA), Operator Localization Systems (ITERA).

The project is trying to solve some of the limitations for the successful introduction of collaborative mobile robots and manipulators in industry:

● Collaborative robots are actors in a flexible system, and in accordance with the principles of Industry 4.0, they must understand what they are doing and will need the rest of the system elements (operators, end of lines, storage systems, machining centers, conveyors, etc.). A planning system is necessary that coordinates all these actors in an efficient way.

● Collaborative mobile robots and manipulators are still expensive and difficult to use. The price will be reduced in the coming years with the effect of serial production, and it is also possible to apply a series of technologies aimed at improving quality and reducing operating costs. On the other hand, integration complexity can be reduced by developing new forms and integrated programming environments.

● Robots must be able to deal with the unstructured environment in which we live and perform useful tasks in a safe and efficient way.

ROBOTNIK IN THE PROJECT

Robotnik is responsible for:

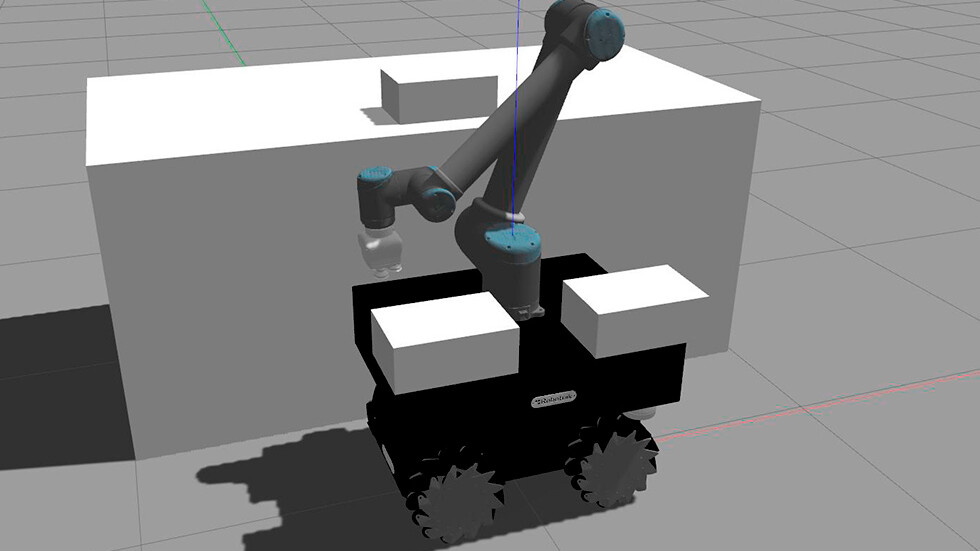

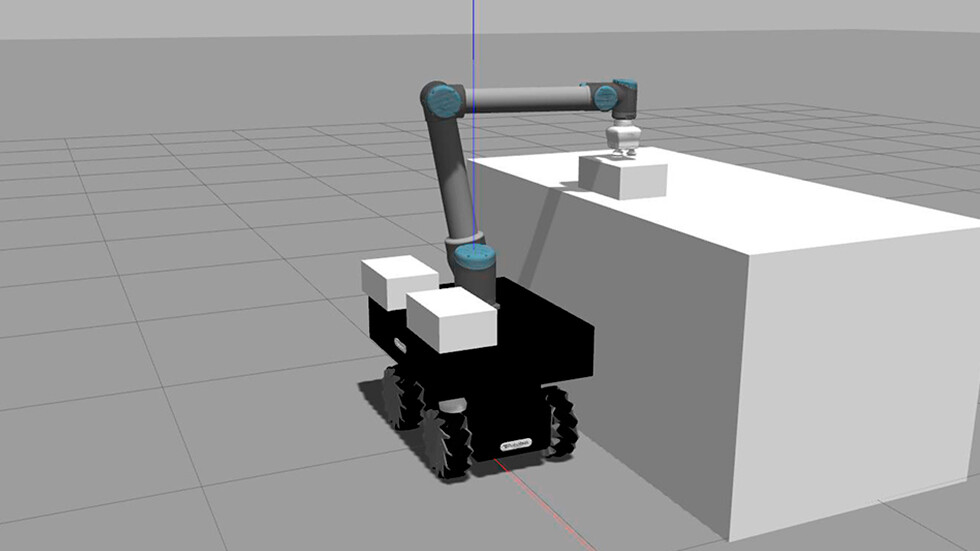

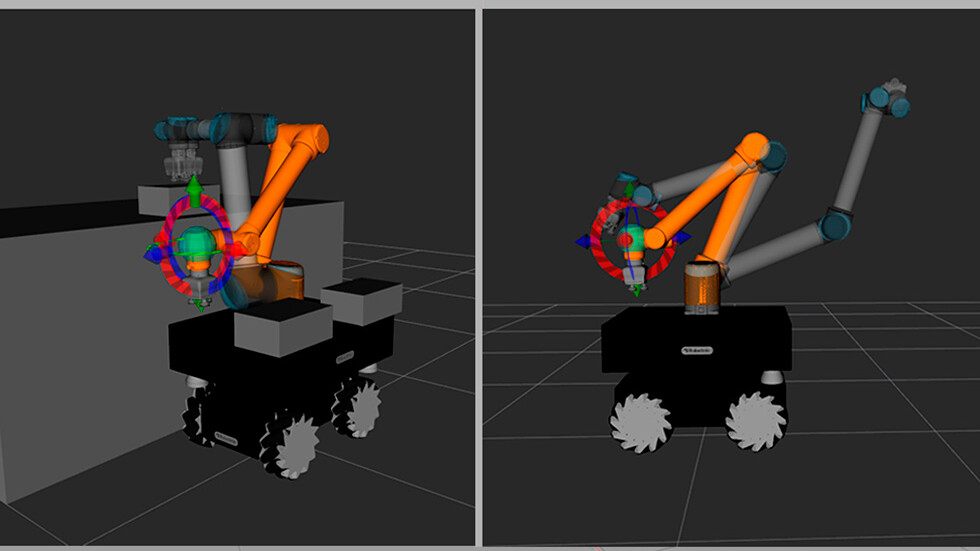

● Development of an integrated programming system for the collaborative mobile manipulator RB-KAIROS.

● New automated QC systems for mobile robot and manipulator production.

● Methods and sensors for the accurate repositioning of the end effector.

● Interconnection of the robot fleet in the cloud and Cloud Fleet Management System

Expected outcomes:

● Product RB-KAIROS+ (URCAPS sw plugin)

● 3 working pilots

● QC for the production line

● Cloud FMS

More projects

SYMPHONY