Mobile Manipulators Range

Our portfolio includes a wide variety of products for the development of industrial applications and R&D in Service Robotics

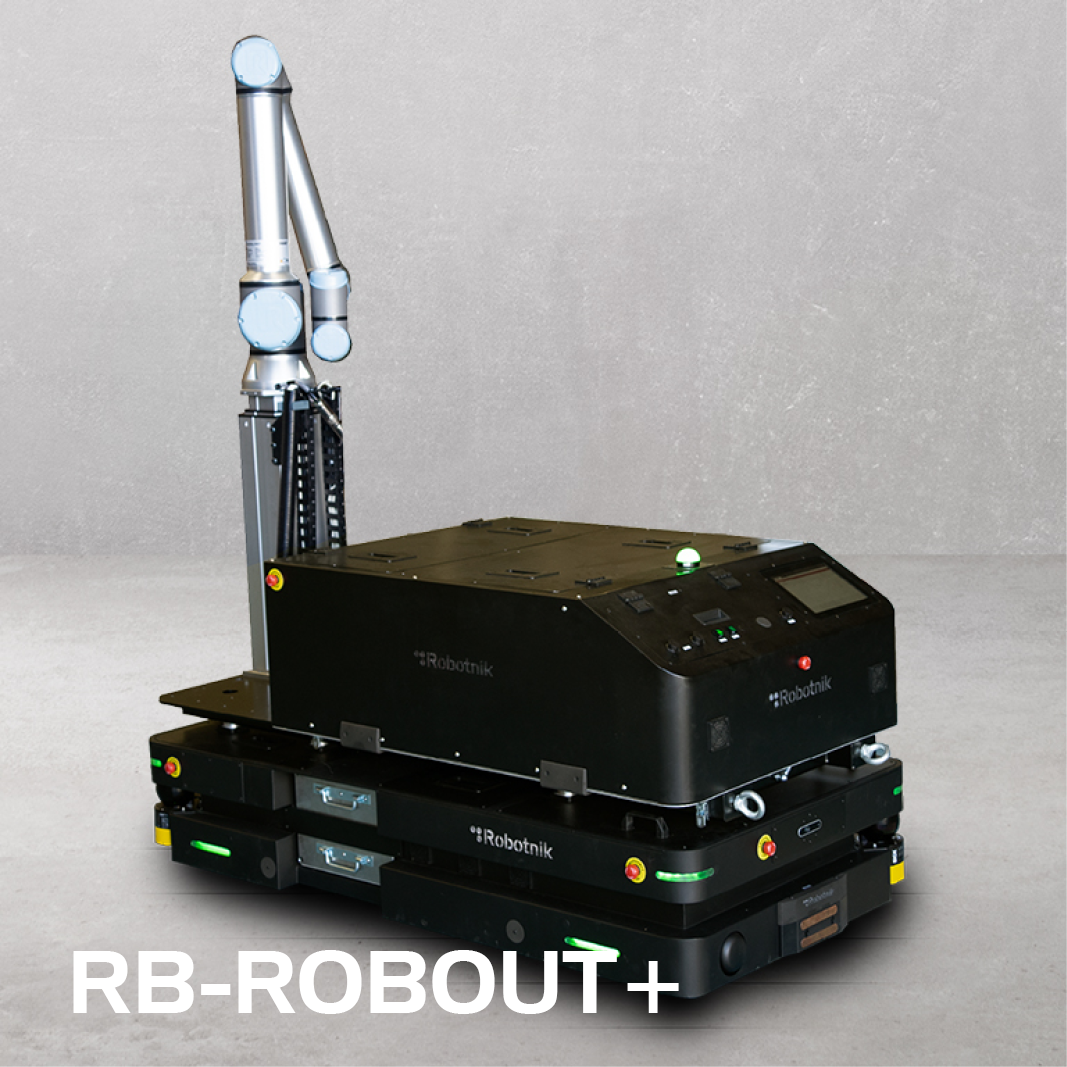

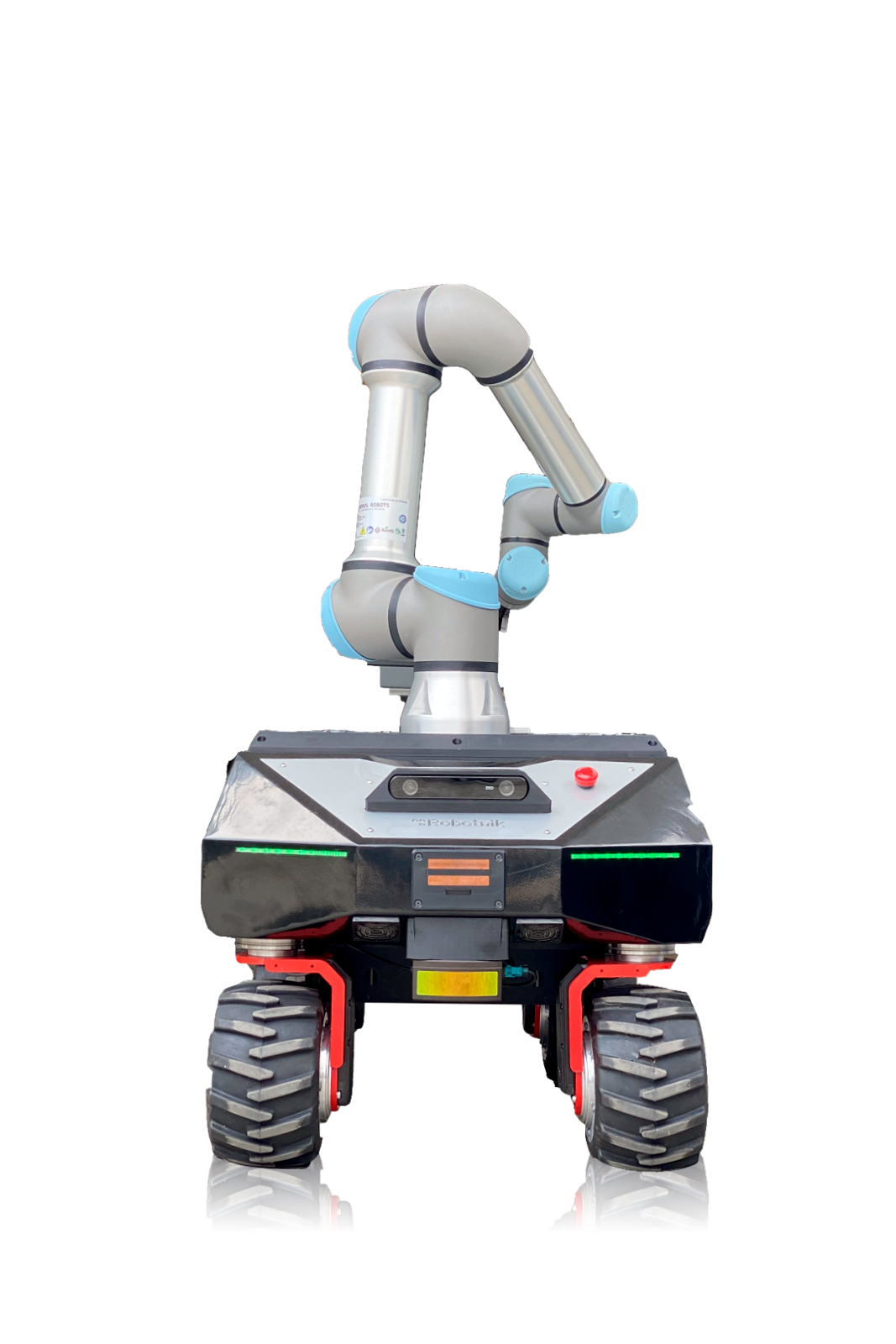

An autonomous mobile manipulator robot integrates a manipulation system (usually a robotic arm) with an autonomous locomotion system (such as wheels, legs, or platforms). This allows the precision and dexterity of a robotic arm to be combined with the autonomy and flexibility of a mobile base. Robotnik, a pioneer in this field, has been developing and manufacturing autonomous mobile manipulators for various sectors such as manufacturing, logistics, healthcare, agriculture, and R&D. Explore our range of mobile manipulators designed for indoor or outdoor environments, with different capacities for diverse tasks.

Mobile Manipulators Range

Our portfolio includes a wide variety of products for the development of industrial applications and R&D in Service Robotics

An autonomous mobile manipulator robot integrates a manipulation system (usually a robotic arm) with an autonomous locomotion system (such as wheels, legs, or platforms). This allows the precision and dexterity of a robotic arm to be combined with the autonomy and flexibility of a mobile base. Robotnik, a pioneer in this field, has been developing and manufacturing autonomous mobile manipulators for various sectors such as manufacturing, logistics, healthcare, agriculture, and R&D. Explore our range of mobile manipulators designed for indoor or outdoor environments, with different capacities for diverse tasks.

Robotnik’s Autonomous Mobile Manipulators are among the most advanced on the market, featuring sophisticated software and hardware. Equipped with various sensors, control systems, and algorithms, these robots can perceive their environment, make decisions, and perform complex tasks with minimal human intervention.

The primary advantage of mobile manipulators over static robotic arms is their versatility, enabled by the mobility of the platform. This allows them to perform tasks in different locations, such as Pick & Place, assembly, quality control, transportation of materials or parts and screwdriving, among others.

Mobile manipulators are especially useful for collaborative applications where they share workspace with humans without needing a restricted security perimeter.

With over 20 years of experience in developing and manufacturing autonomous mobile manipulators, Robotnik has witnessed the significant evolution of these robots. Today, they perform manipulation tasks with great precision, repeatability, and efficiency across various industries. While they are most common in logistics and manufacturing, mobile manipulators are also used in agriculture, automotive, aerospace, and chemicals.

Explore our use cases showcasing Robotnik’s mobile robot manipulators automating handling tasks in different companies. A range of tools and end effectors are compatible with Robotnik manipulators, including grippers, suction cups, robotic hands, automatic screwdrivers, polishing tools, and welding tools. Integrate or exchange the appropriate tool for the task, enabling one robot manipulator to perform multiple tasks at different locations.

A collaborative mobile manipulator operates and navigates in the same space as humans, thanks to integrated navigation sensors, advanced security lasers, and obstacle detection systems. Deploying these robots is simpler than fixed industrial robotic arms, which require prior infrastructure adaptation.

Industry 4.0 emphasizes interconnectivity, enabling optimized resource use and enhanced collaboration. Collaborative mobile manipulators play a crucial role in this new industrial landscape by facilitating human-robot collaboration and inter-robot coordination efficiently.

Collaborative mobile manipulation is a powerful tool that automates repetitive, tedious, or dangerous tasks, reducing production costs and maximizing operational profitability.

Robotnik’s Autonomous Mobile Manipulators are flexible, capable of operating in various dynamic environments, both indoors and outdoors. They combine the manipulation abilities of a robotic arm with the mobility of a mobile base. These robots can move autonomously from one site to another while executing tasks such as Pick & Place, assembly, or stock control.

These manipulator robots adapt to a wide variety of tasks without requiring infrastructure modifications. Their mobility allows easy reassignment of tasks to work in different locations. Depending on operational needs, the end of arm tool (EOAT) can be changed, with options ranging from grippers and suction cups to robotic hands, sanders, or screwdrivers.

Another significant advantage of Autonomous Mobile Manipulators is scalability, allowing companies to gradually increase the number of robots based on production needs. This scalability facilitates expansion and adaptation to market demand without heavy initial investment, as no major infrastructural changes are required.

Robotnik’s intuitive Advanced User Interface (HMI) enhances user control over the Autonomous Mobile Manipulator, optimizing productivity and reducing downtime. Operators manage and control the robot in real-time, both remotely and in person, based on the current position and availability of each robot.

Selecting the right Autonomous Mobile Manipulator involves considering several key factors:

- Assess Operational Needs: What tasks need automation? What are the working conditions?

- Load Capacity and Range: Evaluate the robot's load capacity and handling range, as well as its accuracy and repeatability.

- Autonomy and Navigation: Ensure the robot has advanced sensors for efficient navigation, obstacle avoidance, and adaptability to environmental changes.

- Ease of Programming and Integration: The robot should be easy to program and integrate with other systems, facilitating deployment without extensive training.

- Scalability and Flexibility: Consider the robot's ability to scale and adapt to changing operational needs.

Robotnik’s experts guide customers through the automation process to ensure informed decisions. Choosing the right Autonomous Mobile Manipulator is crucial for advancing your industry. Request a free automation consultation.

Mobile Manipulators Range

An autonomous mobile manipulator robot integrates a manipulation system (usually a robotic arm) with an autonomous locomotion system (such as wheels, legs, or platforms). This allows the precision and dexterity of a robotic arm to be combined with the autonomy and flexibility of a mobile base. Robotnik, a pioneer in this field, has been developing and manufacturing autonomous mobile manipulators for various sectors such as manufacturing, logistics, healthcare, agriculture, and R&D. Explore our range of mobile manipulators designed for indoor or outdoor environments, with different capacities for diverse tasks.

Robotnik’s Autonomous Mobile Manipulators are among the most advanced on the market, featuring sophisticated software and hardware. Equipped with various sensors, control systems, and algorithms, these robots can perceive their environment, make decisions, and perform complex tasks with minimal human intervention.

The primary advantage of mobile manipulators over static robotic arms is their versatility, enabled by the mobility of the platform. This allows them to perform tasks in different locations, such as Pick & Place, assembly, quality control, transportation of materials or parts and screwdriving, among others.

Mobile manipulators are especially useful for collaborative applications where they share workspace with humans without needing a restricted security perimeter.

With over 20 years of experience in developing and manufacturing autonomous mobile manipulators, Robotnik has witnessed the significant evolution of these robots. Today, they perform manipulation tasks with great precision, repeatability, and efficiency across various industries. While they are most common in logistics and manufacturing, mobile manipulators are also used in agriculture, automotive, aerospace, and chemicals.

Explore our use cases showcasing Robotnik’s mobile robot manipulators automating handling tasks in different companies. A range of tools and end effectors are compatible with Robotnik manipulators, including grippers, suction cups, robotic hands, automatic screwdrivers, polishing tools, and welding tools. Integrate or exchange the appropriate tool for the task, enabling one robot manipulator to perform multiple tasks at different locations.

A collaborative mobile manipulator operates and navigates in the same space as humans, thanks to integrated navigation sensors, advanced security lasers, and obstacle detection systems. Deploying these robots is simpler than fixed industrial robotic arms, which require prior infrastructure adaptation.

Industry 4.0 emphasizes interconnectivity, enabling optimized resource use and enhanced collaboration. Collaborative mobile manipulators play a crucial role in this new industrial landscape by facilitating human-robot collaboration and inter-robot coordination efficiently.

Collaborative mobile manipulation is a powerful tool that automates repetitive, tedious, or dangerous tasks, reducing production costs and maximizing operational profitability.

Robotnik’s Autonomous Mobile Manipulators are flexible, capable of operating in various dynamic environments, both indoors and outdoors. They combine the manipulation abilities of a robotic arm with the mobility of a mobile base. These robots can move autonomously from one site to another while executing tasks such as Pick & Place, assembly, or stock control.

These manipulator robots adapt to a wide variety of tasks without requiring infrastructure modifications. Their mobility allows easy reassignment of tasks to work in different locations. Depending on operational needs, the end of arm tool (EOAT) can be changed, with options ranging from grippers and suction cups to robotic hands, sanders, or screwdrivers.

Another significant advantage of Autonomous Mobile Manipulators is scalability, allowing companies to gradually increase the number of robots based on production needs. This scalability facilitates expansion and adaptation to market demand without heavy initial investment, as no major infrastructural changes are required.

Robotnik’s intuitive Advanced User Interface (HMI) enhances user control over the Autonomous Mobile Manipulator, optimizing productivity and reducing downtime. Operators manage and control the robot in real-time, both remotely and in person, based on the current position and availability of each robot.

Selecting the right Autonomous Mobile Manipulator involves considering several key factors:

- Assess Operational Needs: What tasks need automation? What are the working conditions?

- Load Capacity and Range: Evaluate the robot's load capacity and handling range, as well as its accuracy and repeatability.

- Autonomy and Navigation: Ensure the robot has advanced sensors for efficient navigation, obstacle avoidance, and adaptability to environmental changes.

- Ease of Programming and Integration: The robot should be easy to program and integrate with other systems, facilitating deployment without extensive training.

- Scalability and Flexibility: Consider the robot's ability to scale and adapt to changing operational needs.

Robotnik’s experts guide customers through the automation process to ensure informed decisions. Choosing the right Autonomous Mobile Manipulator is crucial for advancing your industry. Request a free automation consultation.

Main Advantages of our Mobile Manipulators

Easy configuration

Quick and simple to set up open software in ROS

Autonomy

Operating during full shifts 24/7 Autonomous docking station

Collaborative

Lasers and advanced security sensors to share work space with people

Omni-directional movement

Allows the reduction of times, making it 1 to 5 times faster than a differential

Advanced User Interface (HMI)

Intuitive control and monitoring of the robot by the end user

Our latest Mobile Manipulators

Do you have an industrial project in mind with mobile robots or mobile manipulators? Talk to us!