The definition of an industrial robot system has evolved considerably in recent years.

In order to determine what an industrial robot is, it is useful to consider the changes from their origin to the present day.

The first robots were precisely industrial robots seen as machines capable of executing certain repetitive and fairly static movements.

Today, as technology advances, it is more complex to differentiate between what is an industrial robot, what is a service robot and how to delimit their working areas.

In the World Robotics 2021 report, it is determined that the classification into industrial robot or service robot is made according to their intended application. Industrial robots are robots “for use in industrial automation applications”, while a service robot “performs useful tasks for people or equipment, excluding industrial automation applications”.

The truth is that inside the industry there are scenarios where robots and humans have to share space and tasks, and therefore, industrial robots are no longer restricted to a safety zone.

More and more often, we find service robots by definition working in industrial applications.

In fact, in the so-called Industry 4.0, collaborative robots play a key role. Today, we would not be talking about collaborative robotics without the prior development of industrial robots systems and their journey towards intelligent automation solutions based on human interaction.

Industrial robot definition

So, what is an industrial robot? An industrial robot is one that has been developed to automate intensive production tasks such as those required by a constantly moving assembly line. As large, heavy robots, they are placed in fixed positions within an industrial plant and all other worker tasks and processes revolve around them.

The characteristics of industrial robots will vary according to the manufacturers, the needs and the scenario in which they are to be located.

According to the international standard ISO 8373:2012, the industrial robot definition is ‘a multifunctional, reprogrammable, automatically controlled manipulator, programmable in three or more axes that can be fixed in one area or mobile for use in industrial automation applications’.

Industrial robots are not usually humanoid in form, although they are capable of reproducing human movements and behaviours but with the strength, precision and speed of a machine.

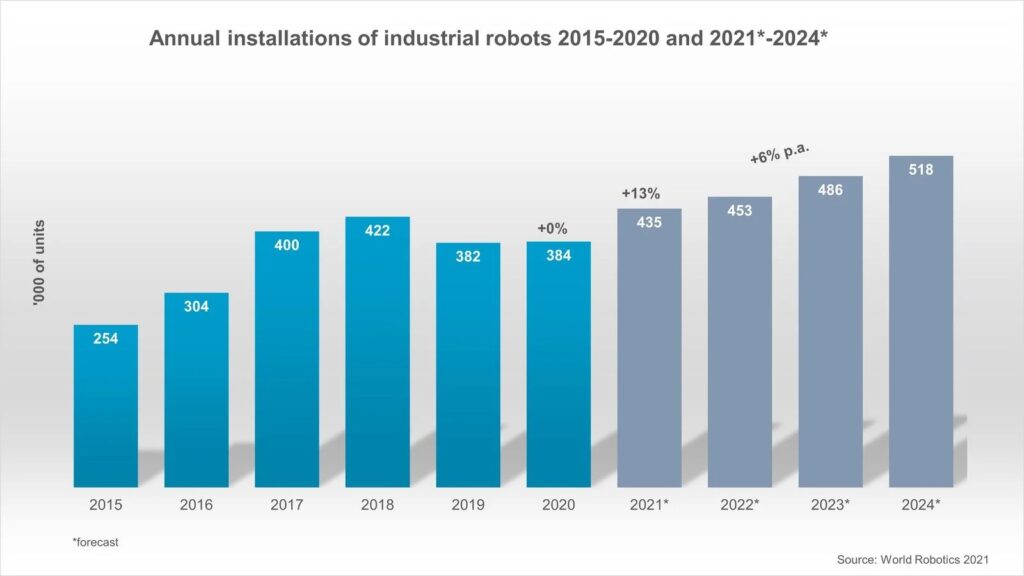

This following table extracted from the World Robotics 2021 report shows the evolution and forecast of mobile robot installations per year.

After that, here are some distinctions that are often confused within the industrial robotics sector:

• Industrial robot and service robot: The difference here is done according to its intended application. As we read in IFR’s ‘World Robotics 2021’ report: Industrial robots are robots “for use in industrial automation applications” while a service robot “performs useful tasks for people or equipment, excluding industrial automation applications”.

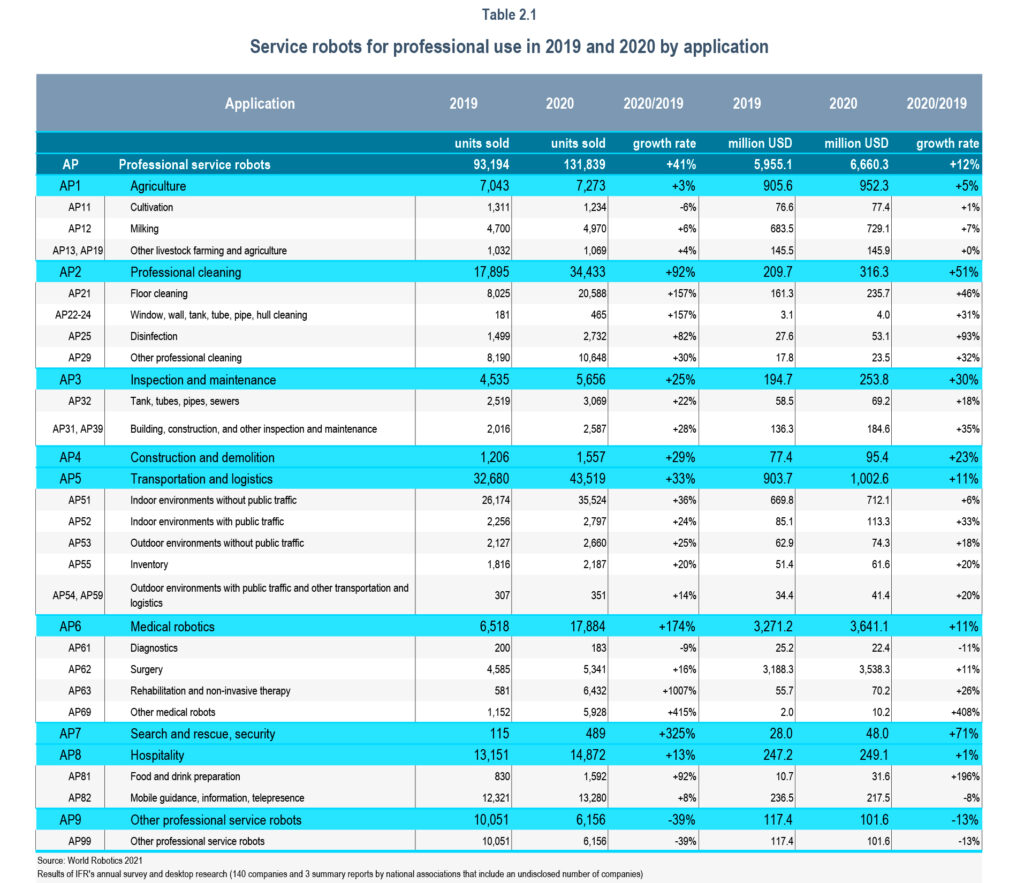

According to the same report, the market for professional service robots grew by 12% in 2020, from a sample turnover of $6bn to $6.7bn. In addition, the global pandemic created new opportunities and additional demand for some service robot applications, e.g. cleaning or disinfection applications or other tasks in the healthcare sector such as telecare, transportation of food or supplies, administrative and logistical tasks, etc.

In fact, industrial robot components are increasingly being modified for applications outside the manufacturing environment. The aim is the integration of industrial robot systems into new markets, as in the example of robots in the healthcare sector above.

• Industrial robot and autonomous mobile robot: Autonomous Mobile Robots (AMR) are often used in industrial environments, but they do not meet the definition of an industrial robot as such: they have no manipulation capability and no three axes.

• Autonomous Mobile Robot (AMR) and Mobile Manipulator: The IFR classifies AMRs as service robots although, as discussed in the previous point, they are often used in industrial environments. If the AMR platform is equipped with a robotic arm, it becomes a mobile manipulator and would therefore count as an industrial robot.

Robotnik as a manufacturer of mobile robotic systems and as the above IFR classification states, is an expert in the development of AMR and mobile service manipulators, often marketed in industrial environments.

Where are industrial robots used?

Nowadays, it is not only large companies that have access to industrial robots. More and more SMEs are experiencing an increase in profitability and a reduction in production costs by automating certain processes.

One of the objectives of industrial robotics is to optimise production lines making them more agile and adaptable to the specific needs of each customer.

Robotnik has been specialised in the development of industrial robotic applications based on platforms and mobile manipulators for 20 years.

Main areas where Robotnik’s industrial robots are integrated:

• Robotics in Logistics: autonomous mobile robots for the transport of materials in different areas and mobile manipulators that extend the working area of static collaborative robotic arms. Some logistics tasks where industrial robots are used are pick and place, metrology, packaging, polishing, screwing or drilling or palletising, among others.

• Robotics for inspection and maintenance: integration of robotic systems equipped with sensors or artificial vision in inspection tasks in areas that are difficult to access or dangerous for operators. These robots can operate autonomously or be controlled remotely by an operator.

Where is service robotics used?

Beyond industrial manufacturing environments, the use of mobile robotics has increased significantly in several sectors:

• Security and rescue: threat detection and assessment, real-time information gathering and transmission, transportation of goods… Autonomous mobile robotics has a lot to contribute in the area of security, rescue and defense.

• Robotics in Agriculture: AMRs are increasingly used for fruit picking, identifying the state of a crop, spraying or sorting to avoid food waste.

• Robotics in Construction: Early error detection, automation of hazardous tasks or monitoring and inspection are just some of the tasks that an AMR can perform in the construction sector.

• Robotics in Healthcare: as mentioned above, it is already common to see collaborative robots in tasks such as transporting food or supplies, surgical assistance, telecare or administrative tasks.

The following table, elaborated by World Robotics 2021, shows the evolution of service robotics by sector and application:

In conclusion

what exactly do industrial robots look like?

After an approach to what an industrial robot is, these are some of the most demanded mobile robots for use in industrial environments:

RB-THERON is an excellent solution for industrial applications such as factories or warehouses, as it is specially designed for autonomous transport of loads indoors.

RB-ROBOUT the solution for the transport of heavy loads in intralogistics, designed to transport loads weighing up to 1 tonne in industrial environments.

RB-KAIROS+: this mobile manipulator is extremely useful for industrial applications such as pick and place, parts feeding, metrology, quality control, screwing of large parts, packaging, cleaning, polishing, screwing, etc. It is designed to work in industrial environments, sharing the work space with operators without risk.

RB-VOGUI+: a versatile mobile manipulator for indoor and outdoor logistics applications. The robot is highly mobile so it is able to follow an operator and navigate autonomously in any industrial environment.