ROS 2 (Robot Operating System): overview and key points for robotics software

For over a decade, ROS (Robot Operating System) has established itself as the reference environment for developing…

What programming language do robots use ?

Every electronic device or machine requires a language both to move and to communicate with other devices, with humans…

Learning ROS online? Is possible thanks to the collaboration of Robotnik and The Construct

If we talk about autonomous mobile robotics, it is essential to talk about ROS. The ROS framework has been one of the…

RB-KAIROS+, the first mobile robot fully prepared to integrate URe arms

Designed for all types of industrial applications, it is presented as a solution for Universal Robots e-Series users.…

ROS Control: the key to consolidate ROS in the robotics industry

ROS has been one of the greatest advances of the robotics industry in the past years. Its development began as a way to…

Robotnik, premium sponsor of 3rd ROS Developers Day

Robotnik is going to sponsor the 3rd ROS Developers Day (*formerly named “ROS Developers Conference“), which is a…

ROS CONTROL, an API to control them all

ROS has been one of the greatest advances of the robotics industry in the past years. Its development began as a way to…

IROS and ROSCon 2016, leading technology and World Robotics Experts meeting

Robotnik has been in the 2016 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2016) and…

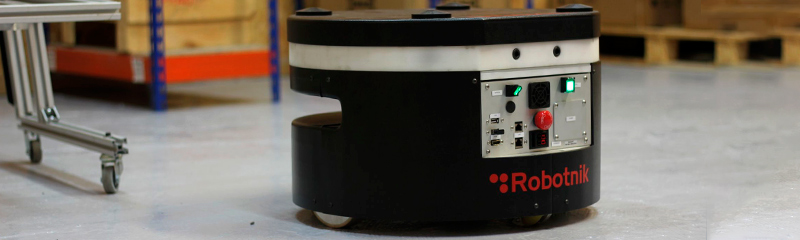

ROS Components, because robotics means ROS

ROS Components is a division of Robotnik Automation Group, leading company in the European service robotics market. The…