Robotics for R&D: Validation of innovations, risk mitigation, and accelerated development

Research and development (R&D) are the driving forces behind innovation in virtually every industrial and…

What is a security robot? What does it do?

Have you ever wondered what is a security robot and what does it do? Come and read. Since 2002, Robotnik has…

What is a mobile robot platform? Inspection in the construction sector

Robotnik answers about what is a mobile robot platform and the applications in construction sector. The use of robotic…

Is it really safe to share workspace between robots and humans? Robotnik in the HR-RECYCLER project

Industry 4.0 and smart factories are a favorable framework for companies that want to grow. Technological sector,…

Robotnik at DECENTER: Mobile robotics + artificial intelligence

Interview PhD- Decenter Project Coordinator. Artificial Intelligence is a technology in constant evolution and its…

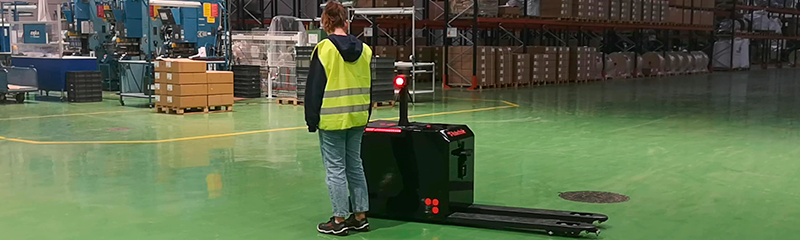

Mobile robots and safety: the experience of Robotnik in HR-RECYCLER project

Collaborative robots have come front and center on the international stage as they’ve become widespread in Industry…

Robotnik in the recycling of electronic waste (E-Waste): HR-RECYCLER

The recycling of electronic waste (E-Waste) is currently the biggest threat to the planet, according to the Global…

BADGER project, the autonomous underground robotic system

Robotnik participates at the BADGER project, whose goal is the design and development of the BADGER autonomous…

Precision viticulture takes another step thanks to the Vinbot project

The European project VINBOT, based on precision viticulture, has just finished after three years of intense work. The…