Complete guide to manipulator robots: benefits and applications

WHAT IS A MANIPULATOR ROBOT?Robot manipulators are robotic systems designed to perform physical manipulation tasks,…

Robotics trends 2024: what will robots be used for?

In 2023, significant changes occurred in the robotics sector, solidifying technologies that undoubtedly expanded the…

2023 in review: robotics trends, technology developments & new robots on the market

2023 has been a year of growth for both Robotnik and the robotics sector in general. In January of this year, Robotnik…

The future is here: Artificial Intelligence robots transforming industries

Artificial intelligence (AI) and mobile robotics have advanced significantly in recent decades and the convergence of…

Advantages and benefits of industrial robots: improving the 4 D's

Since autonomous mobile robotics are part of the industrial scenario, the way in which both production and the…

Recent developments in robotics

Trends and recent developments in robotics that have marked this ending 2022.This article compiles the points that you…

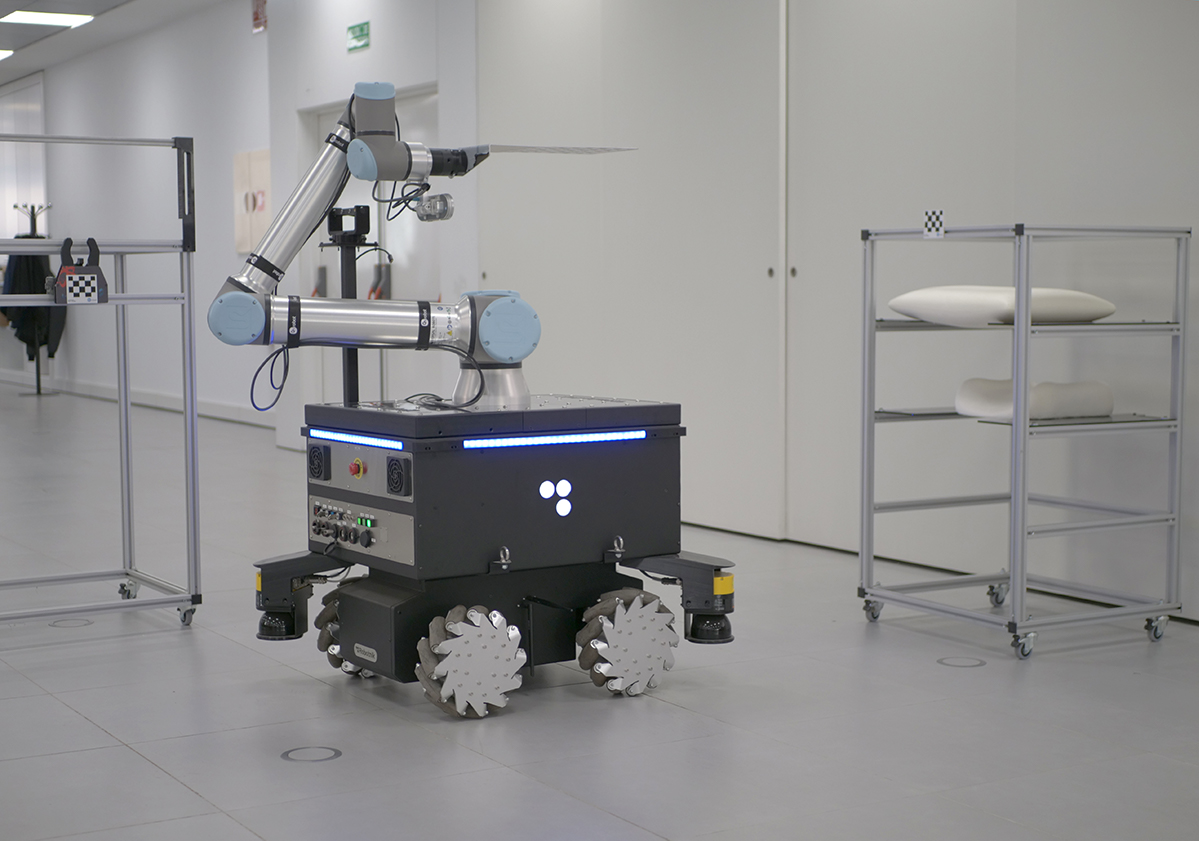

What is a cobot and its benefits?

What is the meaning of ‘cobot’? What is a collaborative robot? What are the benefits of a cobot? These…

Application of robots for material handling

Companies wishing to move towards automation are still uncertain about the technical details of such industrial…