What is the meaning of ‘cobot’? What is a collaborative robot? What are the benefits of a cobot?

These are some of the questions that you usually ask Robotnik through social networks about what is a cobot and what are its benefits for the industry.

In this article we have compiled some of the most frequently asked questions about the cobot universe.

What is the meaning of the word cobot?

Cobot is the short name for collaborative robot. In the late 1990s, both the development of the first collaborative robots and the term cobot itself took place at Northwestern University, by three mechanical engineers.

“an apparatus and method for direct physical interaction between a person and a general purpose manipulator controlled by a computer”.

Brent Gillespie coined the word cobot in 1997 as a more appropriate term.

So, what is a cobot?

Cobot was originally a robot capable of manipulating objects, but over time, the term has evolved to refer to collaborative robots. That is, a robot – manipulator or non-manipulator – developed to work collaboratively with humans and ensure their safety.

The mission of a cobot is to automate industrial or non-industrial tasks by intelligently sharing space with humans. Nowadays, a cobot incorporates advanced technology, sensors, artificial vision and functions that allow it not only to guarantee the operator’s safety, but also to interact by autonomously making the right decisions to optimise the task it performs.

What are the benefits of cobots?

These robotic systems have revolutionised the world of automation. One of the main benefits of cobots is that they have brought robotics closer to small and medium-sized companies that, to date, did not have the capacity to incorporate them. This arises because cobots are versatile and do not always have to perform the same task, but can be redefined according to needs.

Also the designs are more compact than traditional industrial robots and require less physical space to operate, so there is no need for end customers to remodel their infrastructures or install safety barriers.

Not all cobots are user-friendly for the general public. Robtonik cobots are considerably easier to install and operate than traditional robots.

Mobility is another important advantage of the collaborative robots that Robotnik develops.

These benefits of collaborative robots provide greater accessibility, both economically and in terms of usability.

Cobots or collaborative robots are used in many cases to perform repetitive and/or physically heavy tasks, so that workers can focus on other less dangerous tasks.

Improving the safety of workers and their working conditions is one of the goals of cobots.

In order to answer this question with concrete examples, here are some data and statistics from Eurostat on workplace accidents before the worldwide COVID-19 pandemic situation:

EU-wide, the construction, transport and storage, manufacturing and agriculture, forestry and fishing sectors together accounted for about two-thirds (63.1%) of all fatal occupational accidents and more than two-fifths (44.1%) of all non-fatal accidents at work in 2020.

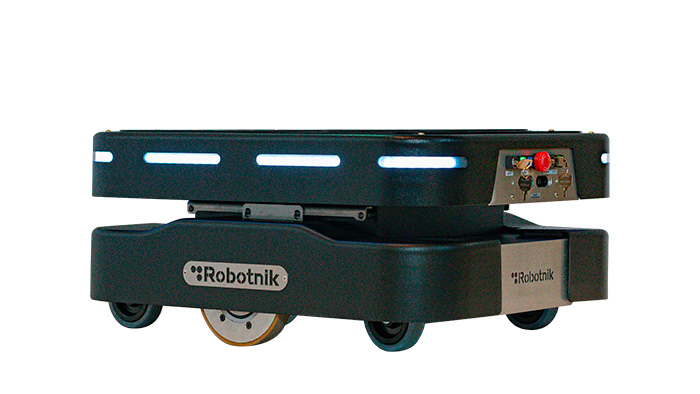

RB-THERON: for transporting loads up to 200 kg in warehouses, factories or indoor environments.

In 2020, more than one fifth (21.5%) of all occupational accidents in the EU occurred in the construction sector, while manufacturing (15.2%) had the next highest proportion and the transport and storage sector (15.0%).

RB-KAIROS+: autonomous mobile manipulator for indoor logistics.

In the EU, two types of injuries were particularly common in 2020, namely wounds and superficial injuries (26.8% of the total) and dislocations, sprains and strains (24.6%).

RB-VOGUI: transport of loads indoors and outdoors up to 200 kg.

Dislocations, sprains and strains accounted for a higher proportion in transport and storage.

RB-ROBOUT: up to 1,000 kg load for indoor goods transport

The incorporation of cobots in the physically hardest workplaces means that these figures are considerably reduced. If you want to avoid many of the work accidents in your factory and the human and economic costs they involve, contact Robotnik to discuss your needs.

Want to know more about what is a cobot and what are its benefits for the industry?