Is it really safe to share workspace between robots and humans? Robotnik in the HR-RECYCLER project

Industry 4.0 and smart factories are a favorable framework for companies that want to grow. Technological sector,…

Robotnik at DECENTER: Mobile robotics + artificial intelligence

Interview PhD- Decenter Project Coordinator. Artificial Intelligence is a technology in constant evolution and its…

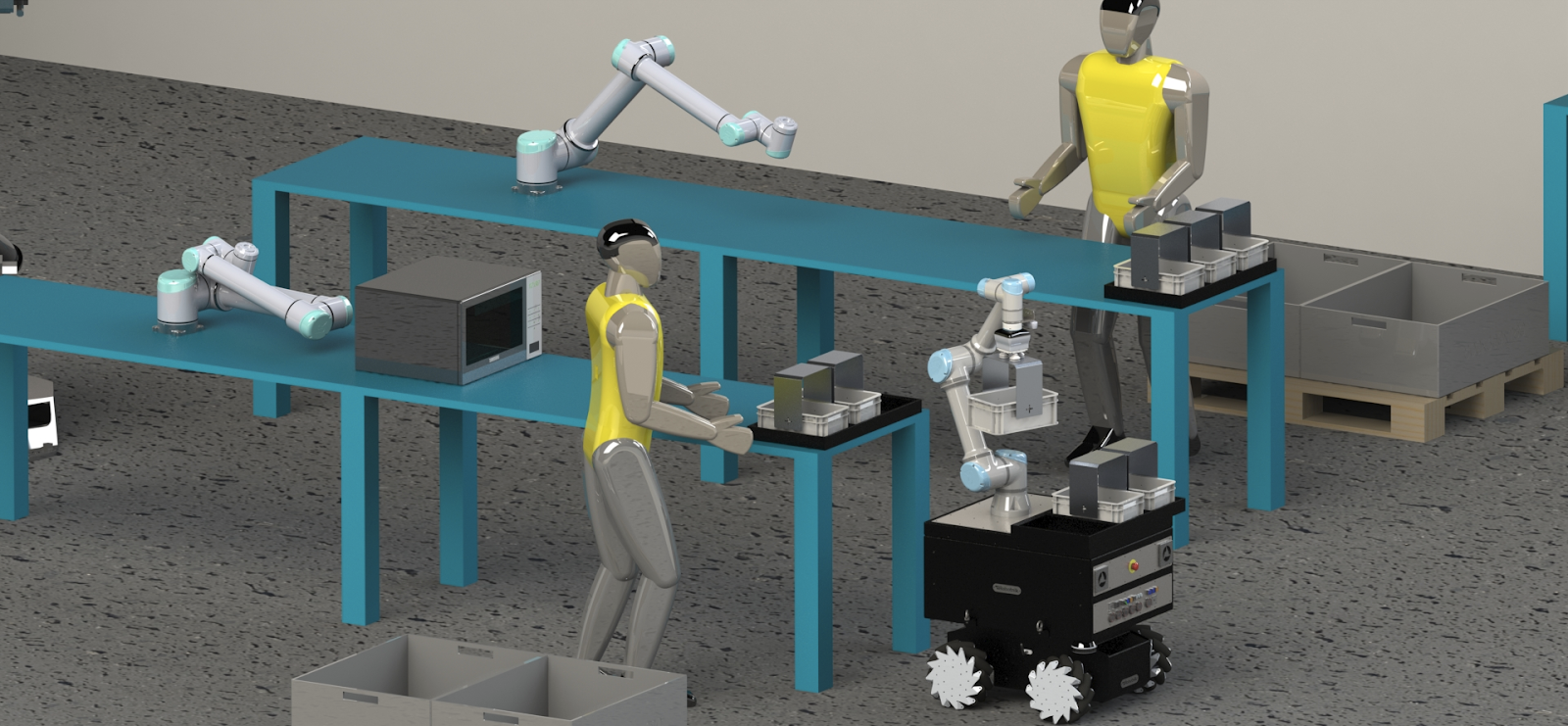

Mobile robots and safety: the experience of Robotnik in HR-RECYCLER project

Collaborative robots have come front and center on the international stage as they’ve become widespread in Industry…

How to use MoveIT to develop a robotic manipulation application

European Commission funded HR-Recycler project aims at developing a hybrid human-robot collaborative environment for…