Interview PhD- Decenter Project Coordinator.

Artificial Intelligence is a technology in constant evolution and its possibilities and influence in different areas is really wide. There are numerous AI applications related to mobile robotics that have a direct relationship with different industrial sectors.

All these applications, as well as the habits of today’s society, make it necessary to focus our attention on one key point: What do we do with the huge amount of data we generate?

Robotnik is part of DECENTER, a European project within the H2020 program whose aim is precisely to manage, protect and process this data efficiently and securely.

Ángel Soriano, responsible for Robotnik in this project, tells us a little more about DECENTER, telling us how it has evolved since its inception, at what stage are the objectives, the conclusions they draw and more.

1. Starting the conversation, could you give us a summary of what exactly DECENTER consists of?

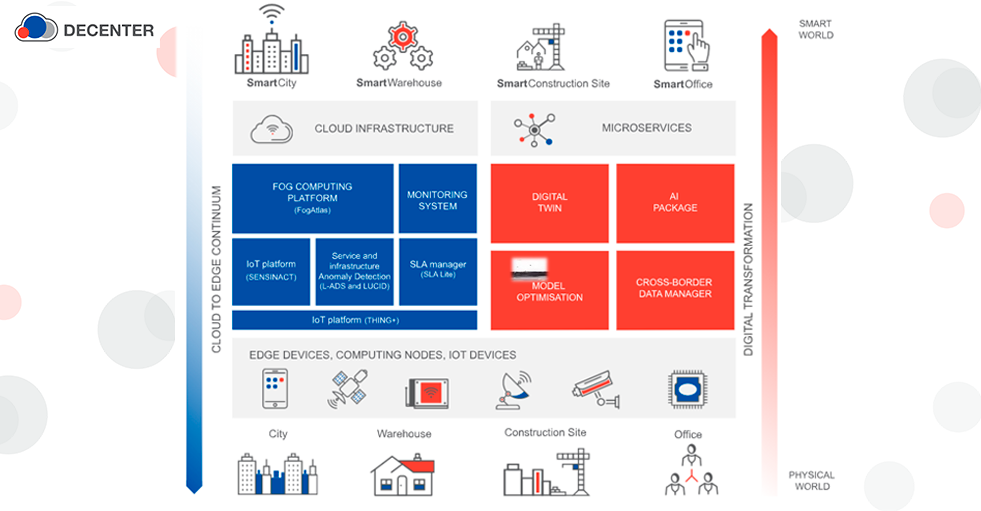

DECENTER is a project that aims to provide an infrastructure that facilitates the integration and deployment of their services or applications to Artificial Intelligence and Cloud&Edge computing oriented software developers.

The project contemplates 3 different profiles:

- Programmers and architects oriented to distributed computing or edge/cloud computing management.

- Developers focused on AI algorithms, which normally require large computational capacity and memory.

- Operators or technical staff responsible for the proper functioning and integration of the software deployed on the available hardware.

DECENTER is intended to make it easier for the technician to integrate AI processes and/or algorithms into the system already deployed in their factory, and also to process them on the edge or in the cloud.

An example: we have a professional who is dedicated to developing an algorithm that is able to identify robots in a photograph. On the other hand, we have a worker-operator who knows his system, who is able to take that photograph, but is not a specialist in Artificial Intelligence. How can he integrate the advantages offered by AI without needing to specialize in it?

DECENTER aims to create these connections and distribute the computation (these algorithms require a lot of computing power) at different levels.

A local level would be to run it inside the same computer that takes the picture.

A level above that would be to run it on a computer that is not the same as the one taking the picture, but is within the same region or relatively close (Edge).

And a level above that would be to run it in the cloud.

By playing with these 3 levels, the project offers a platform that facilitates this integration and communication.

What role does Robotnik play in the project?

Everything explained above applies to 4 use cases that are defined in the project. Robotnik is a supplier of one of the use cases of the project: robotics logistics.

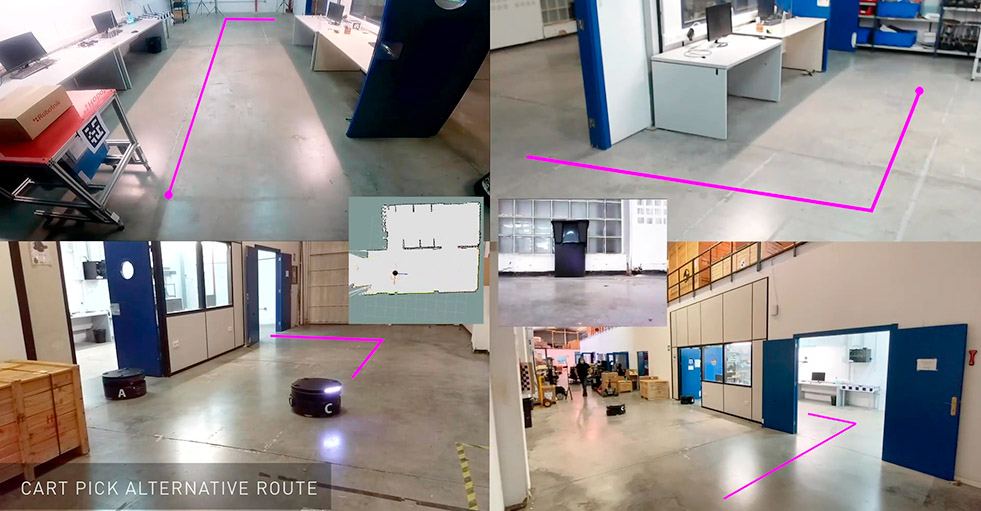

When a robot is performing its autonomous tasks navigating through the warehouse, it has to make certain decisions based on unforeseen events, such as encountering obstacles blocking its path. On certain occasions, if the robot is not able to identify what the obstacle is, the safest option is first for the robot to stop immediately and then to stop:

- Either that the robot remains static waiting until the obstacle disappears to ensure that there is no risk of collision.

- Or for the robot to re-plan its trajectory to reach its target from another location and try to avoid the obstacle.

This is a very common situation in fleets of collaborative mobile robots as they often share workspace with each other and with workers in the same warehouse.

DECENTER opens up the possibility of applying obstacle identification through AI.

Robotnik provides the robots and all the infrastructure, as well as developing the integration of the DECENTER platform within the robot and the structure that we already had and thanks to this service offered by the partner and the project, we have been able to branch out the options for managing fleets of robots in warehouses.

2. At this point, which of the objectives set have been met and in which aspects will it be necessary to continue working on?

An example of an objective achieved in the specific use case of Robotnik is: we set out to be able to identify another robot with a confidence level of more than 80% and to reduce the CPU usage of robots by 10% by deriving computation to the edge/cloud. Both objectives have been successfully achieved.

3. What does this project mean for Industry 4.0?

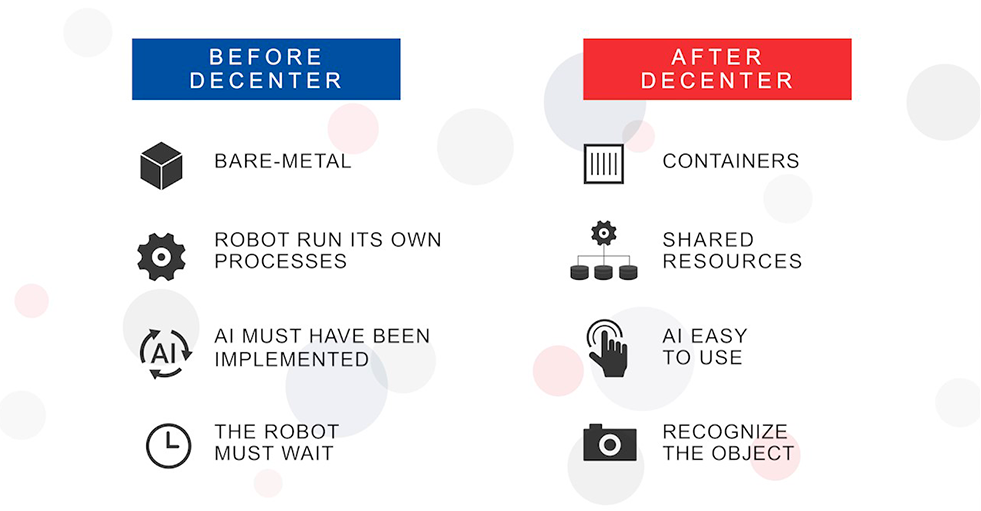

There are several things that DECENTER brings to Industry 4.0 directly. One of them is the management of computing: being able to route and manage computing between devices. Distributed computing is something that is now the order of the day and it’s purely cutting edge. We even talk about doing it in an intelligent way based on objectives or priorities.

In Robotnik we design and manufacture mobile robots. If we want a robot to run a very heavy algorithm and with a lot of computational capacity (this happens in many occasions: high resolution cameras, LiDAR that captures 320.000 different points every second…), we must enable it to do so.

The straightforward solution is for the robot’s CPU to be very powerful, which usually means it is more expensive. However, with the ability to delegate computation, you have the possibility to send all that data using communication with other devices or the cloud, compute the data there and apply the returned result to the robot.

This reduces costs from the point of view of robot production, makes the system more intelligent as it reduces the electrical consumption of the robot, optimises energy and in general optimises resources.

4. Taking into account both large companies and SMEs, what is the biggest challenge for the real application of Artificial Intelligence in industry?

The biggest challenge is undoubtedly that AI is constantly evolving and expanding and its integration in industry requires specialized personnel. Currently there is a gap between the specialized AI community and the personnel involved in the industry who have to deal with the problems of their own industry.

DECENTER tries to bring the two profiles together so that industry can benefit from the application of AI without the need to be an AI specialist.

There is another technological challenge involved in applying the DECENTER methodology in a real industry application, communications. When computing is delegated between devices, and these devices require a certain real-time processing speed, communication between devices needs to be fast and secure.

At DECENTER we have worked at several levels:

EDGE. Here you do not need internet to communicate with another device and it is considered a much faster level in terms of communications than the cloud.

The cloud. Here you do need an internet connection to access the servers and it is normally assumed to be slower than EDGE.

Therefore, in general, communications is the great technological challenge of this methodology. Here we could also talk about 5G, which is another field in which Robotnik is actively participating in other projects.

5. Which use cases have had more impact or which sectors have shown interest in DECENTER’s advances?

DECENTER is mainly related to data processing, its speed in data transmission and computational capacity. Computational resources.

All projects have a development process in which use cases are always defined to demonstrate that the development is applicable to real applications. In the end, it is necessary to demonstrate in which areas of interest what is developed during the project will work.

In our DECENTER use case, the stakeholders are anyone who uses logistics robotics.

It can be interesting for any warehouse management, both for the savings it will bring to the company and for the technological and productive leap.

During the DECENTER pilot, the RB-1 BASE was tested with very attractive results. Now I don’t have individual robots, but I have a fleet of computers that ‘help’ each other to optimize processes, not only from a physical point of view, but above all from the data processing and execution of each one of them: if one of your robots is stopped loading, you can use the computer or PC of that robot to process data from the robot that is moving.