What is a security robot? What does it do?

Have you ever wondered what is a security robot and what does it do? Come and read. Since 2002, Robotnik has…

What's new with robotics R&D? Alessandro di Fava give us the keys

One of the competitive values of Robotnik is its long trajectory not only as a manufacturer of mobile robotics, but…

Is it really safe to share workspace between robots and humans? Robotnik in the HR-RECYCLER project

Industry 4.0 and smart factories are a favorable framework for companies that want to grow. Technological sector,…

Interview to Ángel Soriano, manager of R&D projects at Robotnik

Ángel Soriano is the manager of several R&D projects at Robotnik Automation, the leading Spanish company in…

The spanish Vice-president Nadia Calviño visits Valencia to learn first-hand about the Pilotos 5G project

Valencia has been the location to show the advances in 5G technology within the Pilotos 5G project, in which Robotnik,…

Robotnik at DECENTER: Mobile robotics + artificial intelligence

Interview PhD- Decenter Project Coordinator. Artificial Intelligence is a technology in constant evolution and its…

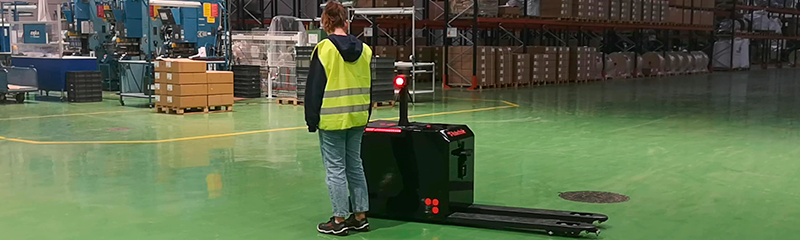

Mobile robots and safety: the experience of Robotnik in HR-RECYCLER project

Collaborative robots have come front and center on the international stage as they’ve become widespread in Industry…

Robotnik in the recycling of electronic waste (E-Waste): HR-RECYCLER

The recycling of electronic waste (E-Waste) is currently the biggest threat to the planet, according to the Global…

Bots2ReC, robotic extraction of asbestos fibres from buildings

Europe has paid a high price for asbestos, with over 100 000 related deaths. First in line in the fight to free…