WHAT IS A MANIPULATOR ROBOT?

Robot manipulators are robotic systems designed to perform physical manipulation tasks, such as lifting, moving and placing objects in different industrial environments without the need for direct contact by an operator.

These traditional industrial manipulators consist, typically, of an articulated mechanical arm that is fixedly installed in the desired location and can be controlled autonomously or teleoperated by a human operator.

The manipulator arm will also carry an end tool (end effector) depending on the application. End tools can be vacuum grippers, grippers, robotic hand, screwdriver, or advanced vision / scanning systems, among others.

The first uses of manipulator arms were, mostly, those that required handling materials in places with difficult access or whose contact was dangerous for humans: radioactive, heavy, high temperatures, high voltage, etc.

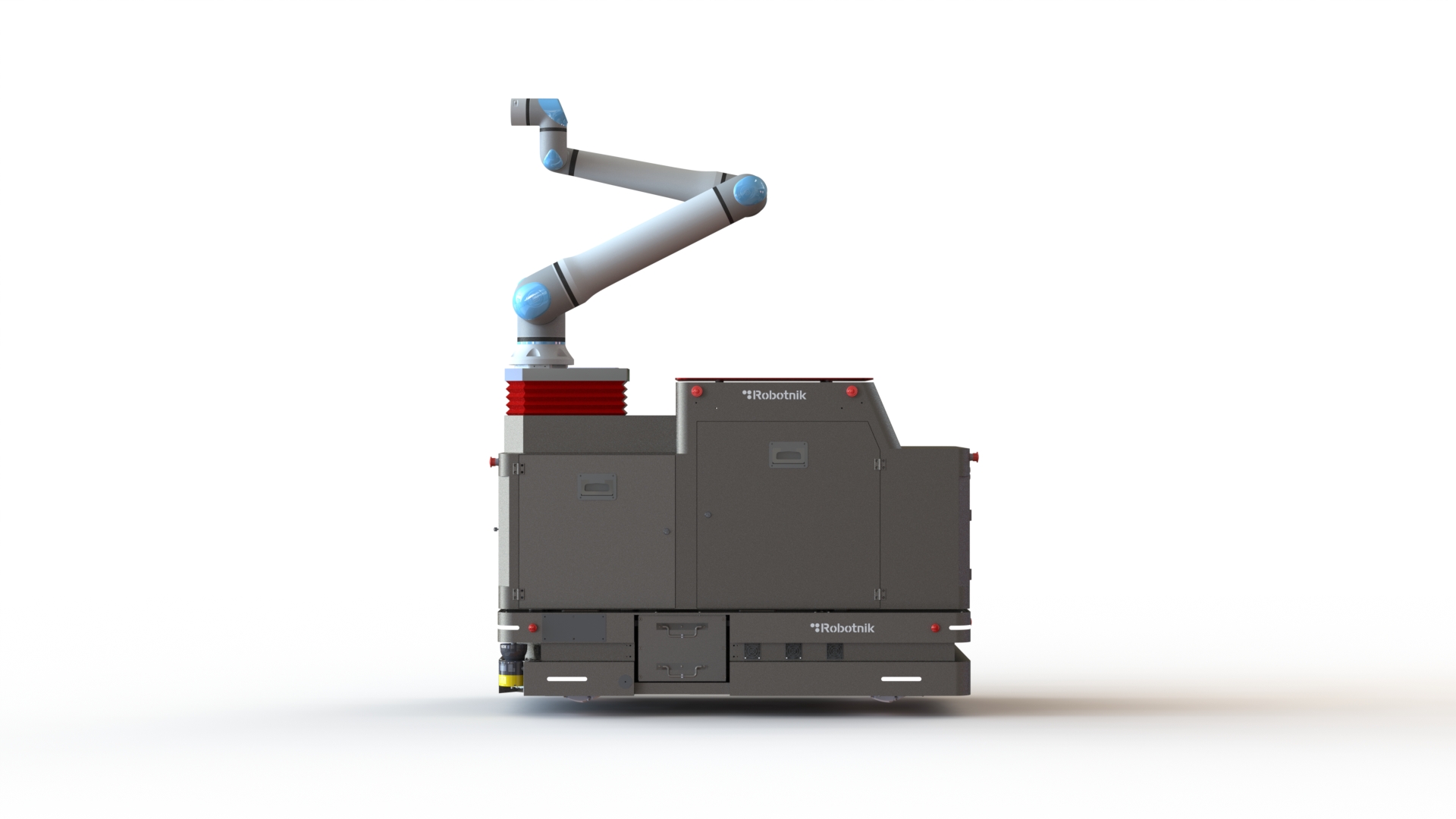

Nowadays, when talking about manipulator robots, we no longer understand only the manipulator arm fixed in a static way, but mobile manipulation appears as an advanced development arising from the integration of a manipulator arm and a mobile robotic platform.

WHAT IS A MOBILE MANIPULATOR ROBOT?

A mobile manipulator is a robot that combines the manipulation capabilities of a robotic arm with the mobility of a mobile platform. That is, a mobile manipulator is capable of moving from one location to another while performing part handling tasks such as lifting, transporting or placing objects. The most frequent mobile manipulation applications are in logistics and warehouses to transport goods between shelves or storage areas, as well as in manufacturing applications to move materials or manipulate parts between different workstations autonomously.

This mobile manipulator can autonomously perform tasks ranging from assembly or assembly of electronic components to quality control.

It is equipped with a combination of sensors and actuators that enable them to understand and respond to their environment efficiently. This includes proximity sensors to detect obstacles and avoid collisions or navigation and localization systems to plan routes and move autonomously in dynamic, unstructured environments.

Improved sensory perception has enabled mobile manipulators to detect and map their environment more accurately, thanks to the integration of advanced sensors such as 3D cameras, LiDAR and ultrasound systems. In addition, the continuous development of path planning algorithms allows them to calculate optimal routes and avoid obstacles in real time, improving efficiency and safety in autonomous navigation. The integration of machine learning systems has also made it easier for mobile robots to learn and adapt to their environment, improving decision-making and optimizing their performance in different tasks and conditions.

.

KEY FEATURES OF MANIPULATOR ROBOTS

One of the main features of robot manipulators is their ability to handle objects of different shapes, sizes and weights with exceptional accuracy and repeatability. This makes them ideal for a wide variety of industrial applications, such as product assembly, material handling on production lines or loading and unloading goods in warehouses and distribution centers.

In addition, manipulator robots are often equipped with a wide range of sensors, such as cameras, force sensors and proximity sensors, which enable them to adapt to the task efficiently. These sensors can be used to detect the presence of objects and obstacles, measure forces and torques during manipulation, and dynamically adjust the robot’s path and speed based on environmental conditions.

Another important feature of robot manipulators is their ability to work in harsh and hazardous environments for humans. For example, manipulator robots are commonly used in welding, painting and nuclear dismantling applications, where they can operate safely in environments with high temperatures, radiation or toxic chemicals.

COLLABORATIVE ROBOTICS: ENHANCING HUMAN-ROBOT INTERACTION

Collaborative tasks in robotics refer to those activities in which robots work in close collaboration with humans or other robots to achieve a common goal. These tasks mean an active, coordinated and safe interaction between the different agents involved, either by sharing information, resources or physical space, in order to perform a task efficiently.

Collaboration in robot manipulators can be in several ways:

-

- Human-robot collaboration: mobile manipulators work together with people to perform a specific task. This can refer to performing physical manipulation tasks together or performing independent but shared tasks in the same workspace.

- Inter-robot collaboration: manipulator robots can also collaborate with other robots to perform complex tasks that require the combination of different skills. For example, several robots can explore and map an unknown environment or coordinate for the different stages of product delivery in an automated warehouse.

Thus, collaborative robotics is set to improve efficiency, accuracy and safety in a wide range of industrial and service applications. This opens up new opportunities for automation and process improvement in various industries, while ensuring a safe and collaborative working environment for workers.

DIFFERENT TYPES OF INDUSTRIAL AUTOMATION

Collaborative mobile manipulation has experienced a remarkable evolution in recent years, advancing in important aspects such as sensing, localization, precision and reach. However, there are still challenges to be faced and much room for improvement in the robotics industry.

How can manipulator robots be optimized to perform collaborative tasks with humans?

To achieve effective and safe collaboration, a holistic approach that addresses design, configuration and safety must be addressed:

-

- Operational capacity: The mobile manipulators available on the market have a limited load capacity on the manipulator arm. The one with the highest load capacity currently available is Robotnik's RB-ROBOUT+ which integrates the UR20 arm and can handle parts up to 20 kg.

- Intuitive interfaces: To facilitate human-robot interaction, it is important to develop intuitive and user-friendly interfaces. This can include touch screens, simplified control panels or even gesture- or voice-based control systems that allow human operators to communicate with the robot in a natural way and without the need for overly complicated training.

- Advanced sensors: equipping robots with advanced sensors, such as cameras and machine vision systems, is essential for them to accurately perceive and understand their environment. These sensors allow the robot to detect obstacles and adjust its behavior accordingly, which is essential in dynamic environments.

- Safe path planning: path planning algorithms are key in human-robot collaboration. These algorithms must both take into account the presence of humans in the environment and optimize the robot's trajectory to avoid collisions and minimize injury risks.

WHAT TASKS CAN MOBILE MANIPULATION ROBOTS AUTOMATE?

Mobile manipulation robots are highly versatile and, as technology advances, can perform a wider range of tasks in different environments. Here are some of the tasks that these robots can perform:

-

- Logistics and material transport: robot manipulators can transport materials and goods from one location to another at different points within warehouses, distribution centers and factories. For example, collecting parts from a storage area and transferring them to a point in the supply chain.

- Automated picking and packing: with the right configuration and sensorization, these robots pick and pick products in warehouses for subsequent packaging. For example, a mobile robot can navigate a warehouse, identify products on shelves and pick them for placement into shipping containers based on customer orders.

- Quality control: automating inspection and quality control frees human teams from a significant workload that is repetitive and mechanical. The repeatability of a robotic arm manipulator ensures accuracy and reliability in detecting faults or defective parts. By equipping a mobile manipulator robot with an end effector such as a vision camera, you enable it to perform safety and quality inspections in industrial environments.

- Assisting hospitals and healthcare clinics: a mobile robot is of great help in assisting hospitals or healthcare clinics by automating logistical tasks such as transporting medical supplies, delivering medication to patients or assisting in the delivery of biological samples to laboratories.

FUTURE TRENDS IN MANIPULATOR ROBOT DEVELOPMENT

Technological innovation is expanding the range of robot manipulation applications. This also means that the manipulator arm is automating tasks more and more precisely, consistently and complexly.

Another important development is the increase in the range of components and end effectors that can be integrated into the robotic arm, depending on the task to be automated. Here you can find some of the options available on the market.

The trend in the industry points to a steady growth in collaborative mobile handling, which is becoming even more relevant due to its versatile, flexible and safe nature.

In conclusion, mobile manipulation robots offer a number of tangible advantages in terms of operational efficiency, product quality and workplace safety. Their ability to perform repetitive tasks with pinpoint accuracy makes them valuable assets in highly demanding manufacturing environments. Furthermore, the integration of advanced sensors and machine vision systems enables real-time error detection and correction, resulting in a significant reduction of waste and associated costs. In terms of safety, robotic manipulators can take on dangerous or tedious tasks, protecting human workers from injury and improving the quality of work life. As we move towards Industry 4.0, demand for robotic manipulators is expected to continue to grow, especially in sectors such as automotive, electronics and logistics. With continued innovation in materials, mechanical design and system control, robotic manipulators are poised to play an even more integral role in optimizing industrial processes and creating safer and more efficient work environments.

FAQs about robotics

A mobile manipulator is a type of robot that combines the object manipulation capabilities of a robotic arm with the mobility of a mobile platform in a single device.

Pick & Place, quality control, assembly, parts transport, screwdriving, drilling or logistics tasks, among many others.

Collaborative robotics is the one that allows robots and humans to work together sharing tasks or workspace, in a safe and efficient way.

READY TO STREAMLINE HANDLING TASKS ACROSS VARIOUS LOCATIONS?

Reach out to our team for expert guidance!