Outdoor mobile robots: definition and key technical requirements

Outdoor Mobile Robotics refers to systems that have been specifically designed and developed with the technical…

Human-Machine Interface in robotics: definition, benefits & future innovations

In robotics, the Human-Machine Interface (HMI) is the control interface that facilitates communication between the user…

Mobile robots applications in the aerospace industry

Robotics in the aerospace industry has evolved beyond its traditional use in sectors such as automotive or electronics,…

AMR (Autonomous Mobile Robots) in various sectors

Autonomous Mobile Robots (AMR) have opened up a wide range of opportunities across various sectors, presenting an…

Applications of robots in the energy and natural resources sector

The oil and gas sector involves hazardous processes and demands a highly specialised workforce. Therefore, the use of…

Robotic trends in 2025: innovations transforming industries

The robotics landscape in 2025 is an example of how innovation continues redefining industries. Robotics together with…

FAQs on Robotics, Deep Learning, and Artificial Intelligence

The fusion of robotics and deep learning is revolutionizing industries by creating smarter, more adaptive machines…

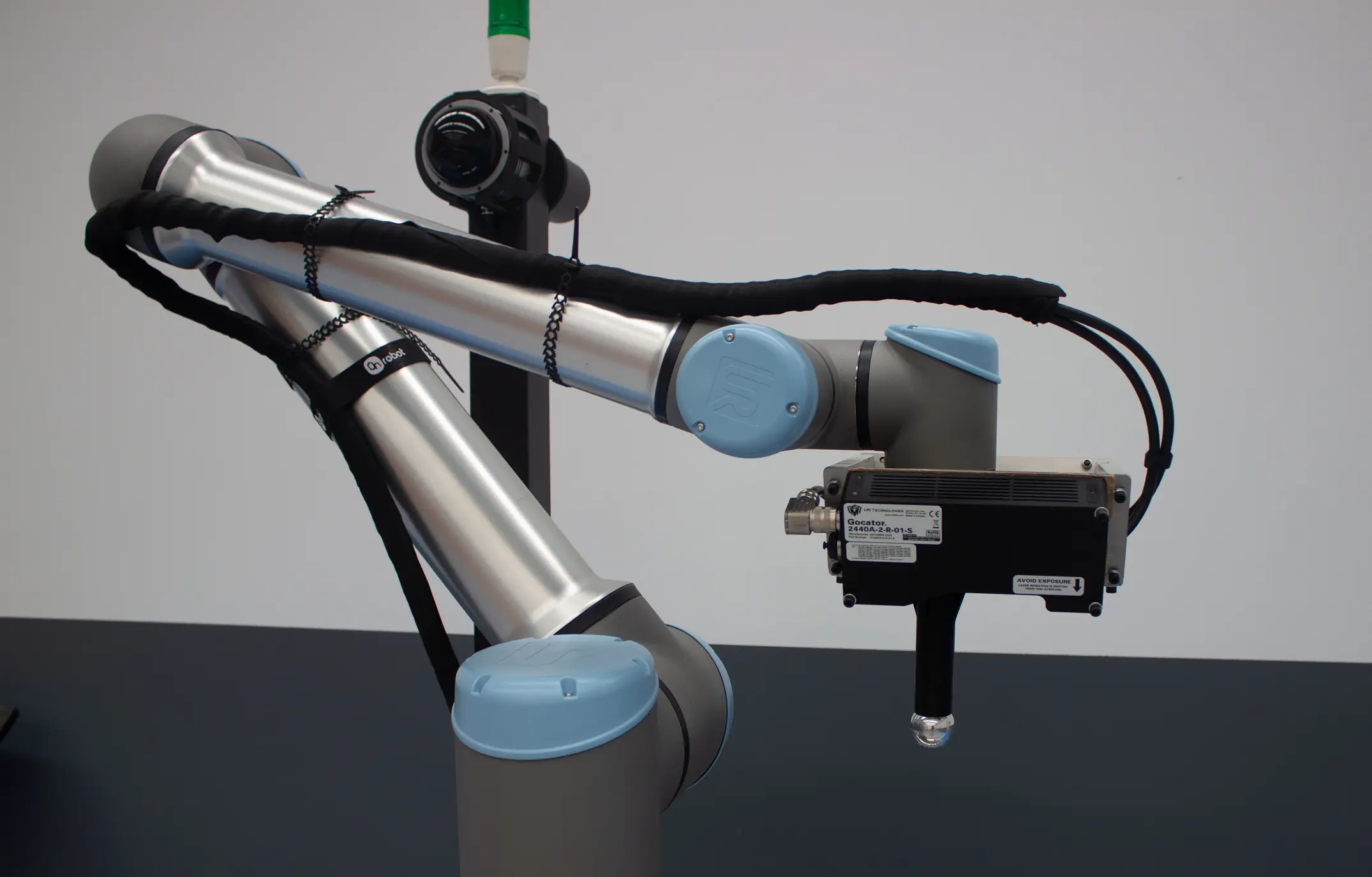

Mobile manipulators: combining mobility and manipulation for diverse environments

Autonomous navigation of AMR (Autonomous Mobile Robots) and manipulation of robotic arms are advanced technologies that…

Robotics for end of line automation: RB-KAIROS+

Within industrial production, the automation of end-of-line tasks is essential to ensure quality and efficiency in…

What are the advantages of mobile robots in warehouse transportation management?

In an increasingly high-pressure supply chain, mobile robotics for the transport of goods in warehouses represent an…