Warehouse automation is by no means a new concept. However, now we are talking about technologies for warehouse automation that are new and that are providing truly promising automation possibilities. Technologies such as Artificial Intelligence, IoT or virtual reality are changing the landscape in most areas, including logistics.

The main objective of warehouse automation is to streamline repetitive, mechanical, and tedious tasks through automated storage systems and robotics in warehouse management, enhancing efficiency and accuracy. Robotics in warehouse management optimizes time- and labor-intensive processes, freeing workers to focus on higher-value tasks.

Facing a global and highly competitive trade, warehouse automation is a short- to medium-term goal for most logistics, distribution and e-commerce companies, which are already adopting innovative solutions to improve efficiency, reduce costs and increase accuracy in the management of their warehouses.

The demand requires speed and precision in a competitive market. This article compiles the latest technologies for warehouse automation, the role of robotics in warehouse management, what a robotic warehouse is like and some examples of Robotnik robots ready to operate in warehouses.

Advantages of Automation in Warehousing and Robotic Storage

Warehouse automation involves using advanced systems and technologies to handle, store, and manage products with minimal or no human intervention. This includes technologies such as:

- Automated storage systems for optimizing space

- Robotic warehouse solutions for automating tasks like sorting and picking

- Warehouse management robots for tracking inventory and transportation These technologies drastically improve efficiency and reduce human error.

Companies that choose warehouse automation technologies have the capacity to cope with the growing demands of e-commerce and today’s complex logistical challenges. Here are some advantages of automating a warehouse:

- Greater efficiency: Automated operations allow larger volumes of products to be handled quickly and accurately, without the physical limitations of manual labor.

- Error reduction: Automation minimizes human errors related to counting, sorting and placing products.

- Space optimization: An automated storage system optimizes the use of vertical space, allowing the company to store more products in less surface area.

- Improved security: By reducing human interaction in dangerous or repetitive tasks, automation directly affects the reduction of risks of workplace accidents.

Key innovations in warehouse automation technologies

Companies are adopting various technologies to improve their warehouse operations. Below are some examples of innovations for warehouse automation.

1. Automated Storage Systems

Automated Storage & Retrieval Systems (AS/RS) allow the storage and retrieval of products by means of automated equipment such as stacker cranes, cranes or conveyors. Automated storage systems are especially useful in high volume, high turnover warehouses, where speed of product retrieval is critical and provide benefits such as:

- Better use of space: AS/RSs allow products to be stored on high-bay racking, maximizing available vertical space.

- Fast retrieval: These systems can access products faster than traditional manual methods.

- Integration with management systems: AS/RSs integrate with warehouse management systems (WMS) and ERP, facilitating real-time inventory tracking and control.

2. How Robotics is Revolutionizing Warehouse Management

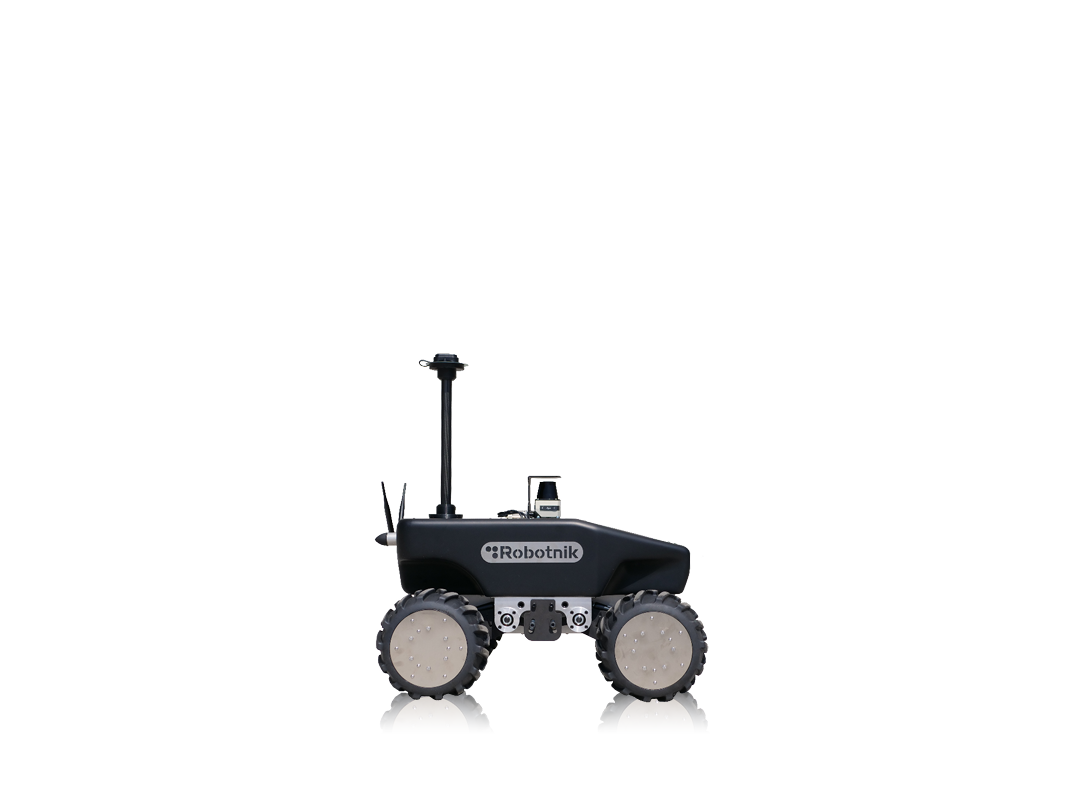

Autonomous Mobile Robots have the ability to automate tasks that are so common in a warehouse such as picking, packaging, inventory control, transportation of goods or the supply of different production lines within a logistics plant.

Among the most common types of robots in warehouse management, we can find:

3. Automated Sorting Systems for Efficient Warehouse Operations

Product sorting and, specifically, order picking is one of the most critical areas in warehouse management. Automated sorting systems are a solution within intralogistics processes to handle large volumes of products in a short time. These systems can range from barcode readers, cameras or other sensors that are installed at strategic points to identify, classify and redirect products according to their final destination.

Can you imagine what these sorting sensors could do in a warehouse if, instead of being fixed at a single point, they were mounted on a self-contained mobile manipulator?

Innovative Warehouse Robots for Automation: Top Examples

Robots and mobile manipulators are capable of automating different tasks within a warehouse or logistics environment: quality control, pick & place, indoor transportation, tool operations on large pieces, handling of chemical or toxic materials, supplying production lines or screwing.

The implementation of AMR in a warehouse maximizes the performance of operations and avoids mechanical, repetitive or dangerous tasks for operators. These are the robots that can execute the above tasks:

Advances in Warehouse Automation Technologies: IoT, AI, and Robotics

As the demand for faster, more accurate logistics operations increases, warehouse automation technologies continue to evolve. Here are some of the most innovative technologies that are driving the way warehouses are managed.

1. Internet of Things (IoT) in warehouses

The Internet of Things (IoT) is enabling warehouses to become more connected and smarter. Through sensors, RFID tags and connected devices, warehouses can collect real-time data on the location, status and movement of products. This enables more comprehensive control of operations and improves inventory control.

IoT also facilitates warehouse automation by enabling robots and automated systems to communicate with each other and with management software, optimizing the workflow of the entire warehouse.

2. Artificial intelligence (AI) in logistics

Artificial intelligence (AI) plays a key role in the management of pretty much any activity, including warehouse automation. Through machine learning algorithms, warehouse robots and other systems can analyze large amounts of data to predict demand, optimize product storage or improve picking accuracy.

AI-equipped warehouse management robots learn by trial-and-error and adjust their behaviors to operate more efficiently, improving time and making smarter decisions.

3. Computer vision and robotics

Computer vision is another technology that is transforming warehouse automation. Computer vision systems enable robots and automated systems to identify and process products using cameras and image recognition algorithms. This is useful, for example, for automated picking, where robots must identify individual products on shelves or conveyor belts.

The future of automation in warehouses

Automation brings benefits to both companies and employees, helping efficiency, agility and safety in production.

For increasingly intelligent and customized warehouse management, automation is emerging as a driving tool that transforms the logistics industry to improve efficiency, reduce costs and increase accuracy in inventory management. The use of automated warehousing systems, advanced robots and emerging technologies such as IoT and AI, allow companies to remain more proficient and better adapt to the flow in demand of a global market that increasingly demands greater accuracy and agility.

Interested in transforming your warehouse operations with the latest automation technologies? Contact us to learn more about how our innovative robotic solutions can improve your logistics efficiency.

FAQs about Warehouse Automation

Automated storage systems, such as Automated Storage and Retrieval Systems (AS/RS), are advanced technologies used to automate the storage and retrieval of products in warehouses. They help maximize space utilization, speed up product retrieval, and integrate with warehouse management systems for real-time inventory tracking.

Robotics in warehouse management automates time-consuming tasks such as picking, sorting, and transporting goods. They enhance efficiency, reduce human errors, and enable warehouses to handle larger volumes of products with minimal human intervention.

Warehouse automation improves operational efficiency, reduces human errors, optimizes space, enhances worker safety, and increases throughput. It also allows companies to meet the growing demands of e-commerce and modern logistics.

Artificial Intelligence (AI) enables warehouse robots and systems to analyze data, predict demand, and optimize workflows. AI-driven robots learn from their environment, make real-time decisions, and continuously improve their operational efficiency.

Common types of robots used in warehouses include Autonomous Mobile Robots (AMRs), Automated Guided Vehicles (AGVs), mobile manipulators, and collaborative robots (cobots). Each type of robot is designed to perform specific tasks such as picking, transporting, or packaging products.