Mobile robots applications in the aerospace industry

Robotics in the aerospace industry has evolved beyond its traditional use in sectors such as automotive or electronics,…

ROS 2 (Robot Operating System): overview and key points for robotics software

For over a decade, ROS (Robot Operating System) has established itself as the reference environment for developing…

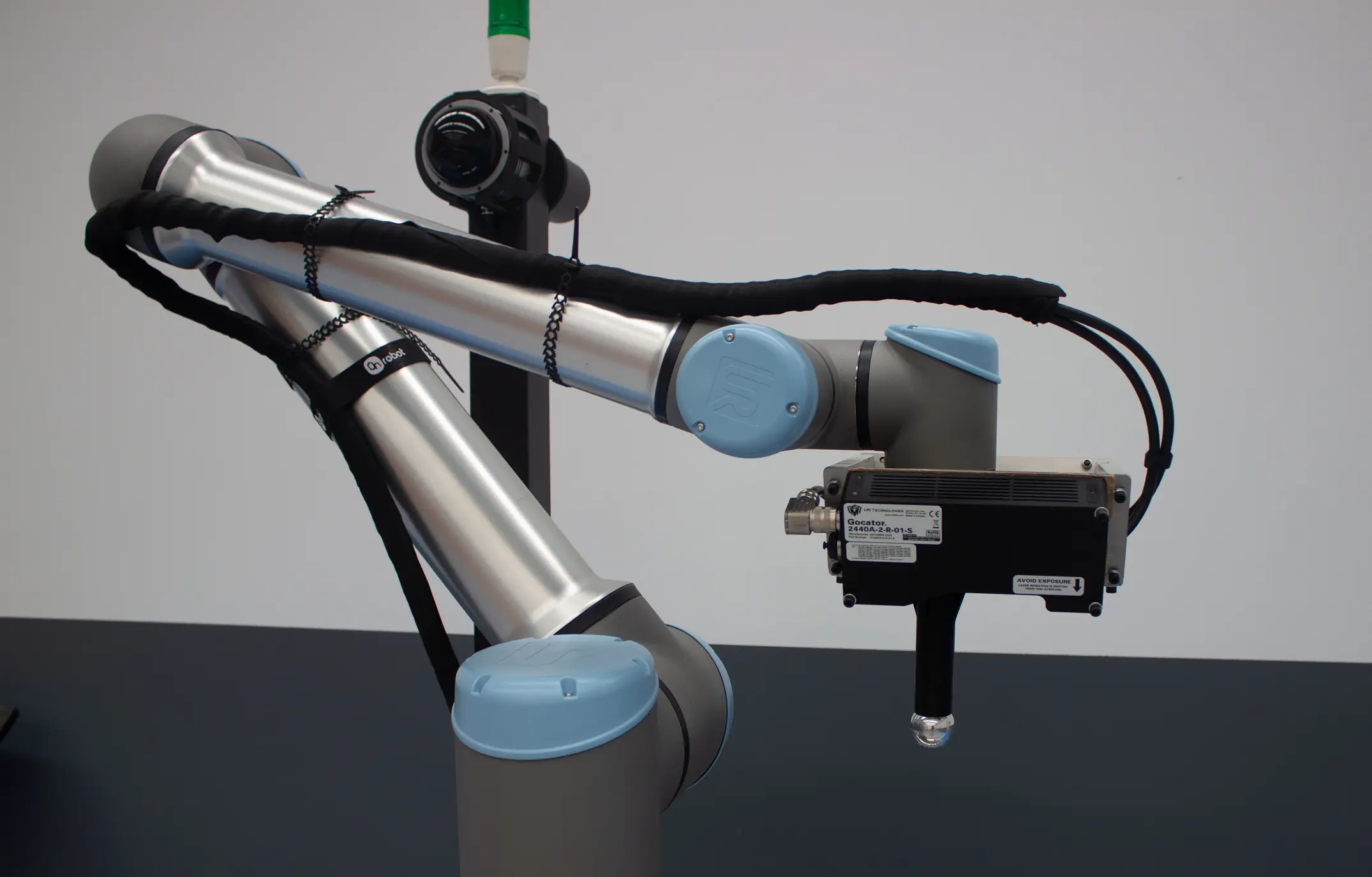

Custom robots in industry and manufacturing

One of the most robotics trends in industry is the customization of robots to meet specific manufacturing needs.…

AMR (Autonomous Mobile Robots) in various sectors

Autonomous Mobile Robots (AMR) have opened up a wide range of opportunities across various sectors, presenting an…

Applications of robots in the energy and natural resources sector

The oil and gas sector involves hazardous processes and demands a highly specialised workforce. Therefore, the use of…

RB-WATCHER: Autonomous Mobile Robot for security and surveillance in ports

RB-WATCHER surveillance robot to improve the security of port entities: the use case of Robotnik in the AER Insight…

Robotics for inventory and stock control: Next step for warehouses

One of the areas that has changed the most within the logistics industry is stock control. Automating stock control…

Top innovations in warehouse automation: automated storage systems

Warehouse automation is by no means a new concept. However, now we are talking about technologies for warehouse…

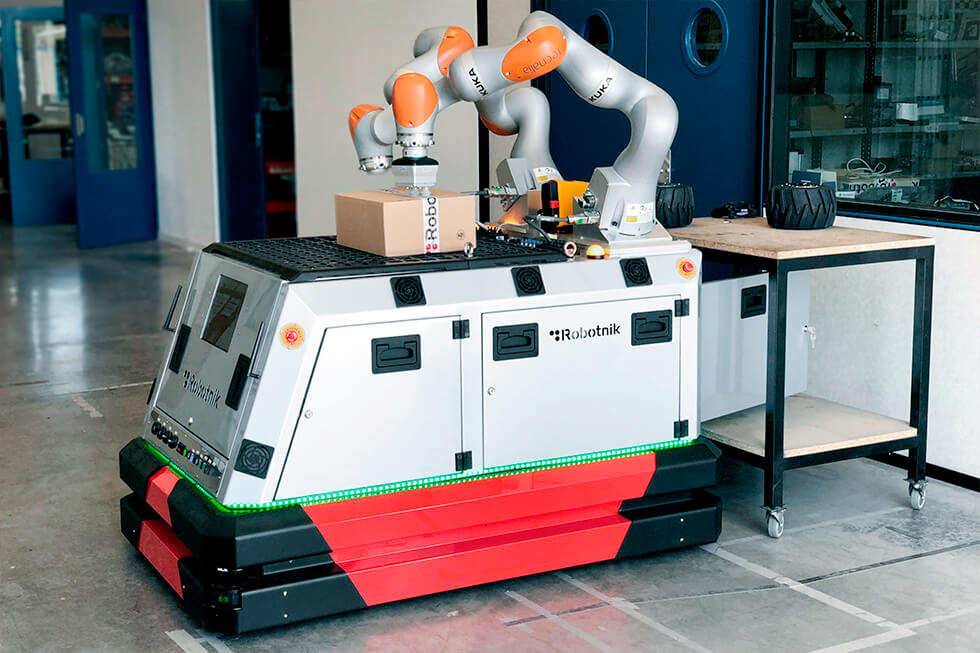

Innovations and applications of industrial mobile robots

The rapid evolution of factory automation is pushing industries to adopt smarter and more efficient technologies. Among…

What are the advantages of mobile robots in warehouse transportation management?

In an increasingly high-pressure supply chain, mobile robotics for the transport of goods in warehouses represent an…