HOW AI POWERS AN AUTONOMOUS INSPECTION AND SECURITY ROBOT

The autonomous mobile inspection and security robot developed by Robotnik, RB-WATCHER, has established itself in 2025 as a technological benchmark thanks to the integration of Artificial Intelligence (AI) and computer vision, which provide advanced real-time perception, detection, and decision-making capabilities.

Thanks to the ongoing improvements of Robotnik’s software team and a period of testing and development, this article demonstrates how RB-WATCHER’s inspection and security operations are enhanced by combining deep learning algorithms, multispectral sensors, and an autonomous mission management system.

Vision recognition architecture

The vision system of RB-WATCHER is composed of a set of high-resolution cameras and complementary sensors, including RGB, thermal, and 3D cameras, that capture visual information from its surroundings.

Through its AI processing modules, the robot interprets these images to detect objects, people, or relevant incidents. Training these models requires large volumes of data representative of the industrial environment. For example, to train a person-detection module, tens of thousands of images are used to teach the AI to distinguish between human silhouettes, moving objects, or background elements.

Thanks to this methodology, RB-WATCHER achieves a high level of accuracy even under poor lighting conditions or in environments with motion and visual noise.

AI integration with autonomous operation

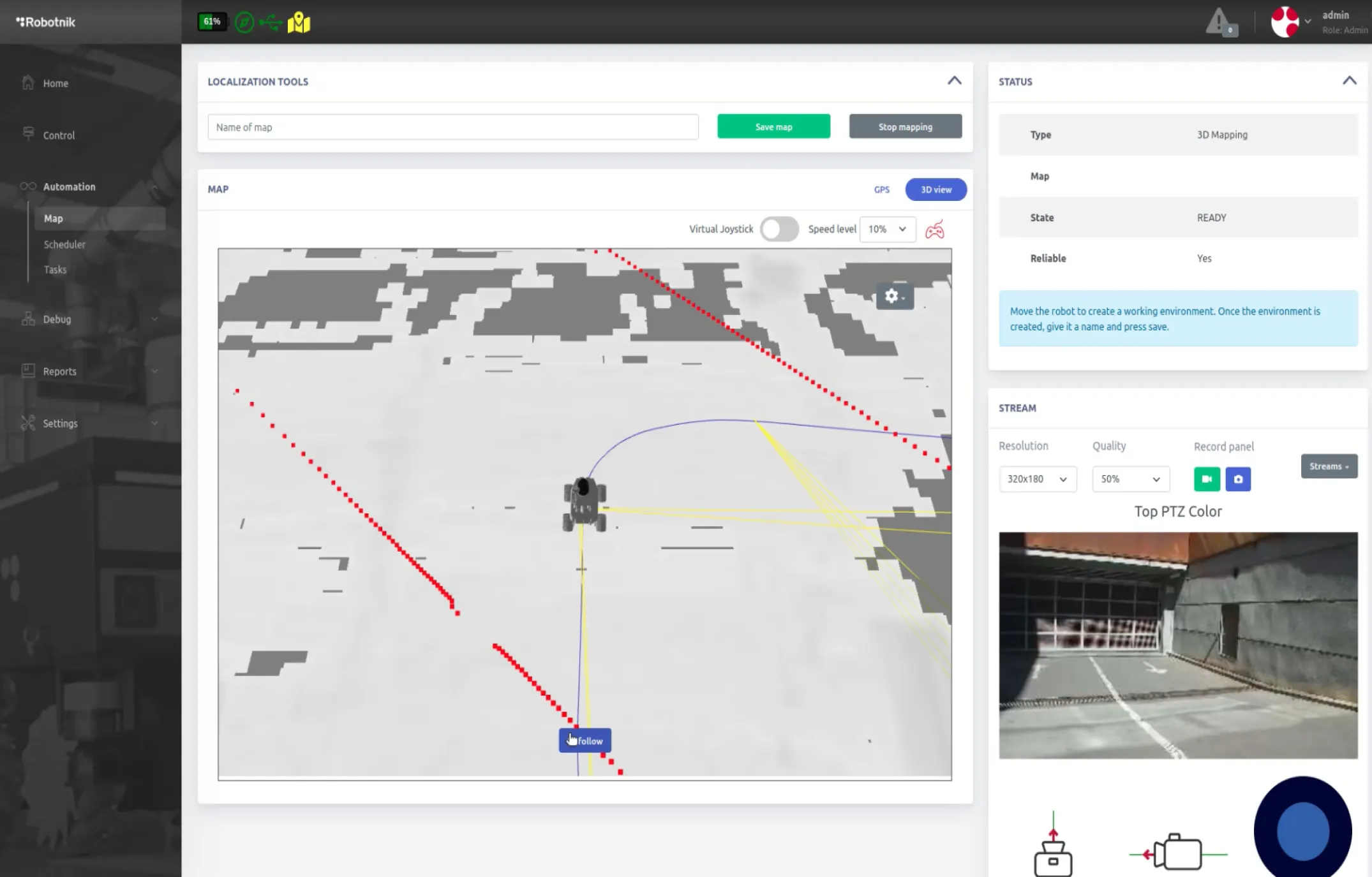

One of RB-WATCHER’s most significant advances is the seamless integration between AI-based vision systems and its autonomous management software, known as the Robot Management System (RMS).

The RMS acts as the robot’s operational brain, a system that manages mission planning, execution, and prioritization, making automatic decisions based on parameters such as battery level, sensor status, or workload.

Main RMS functions

-

- Event management: monitors the execution of missions (start, completion, errors, or cancellations).

- Idle-time control: if the robot remains inactive for too long due to an obstacle or error, the system automatically orders a return to the charging station.

- Smart power management: regulates battery levels, setting thresholds to start, pause, or reject missions based on available energy.

- Advanced energy safety: includes automatic shutdown at critical levels or hibernation protocols if the return-to-dock procedure fails.

Interaction Between AI and RMS

When the vision modules detect an anomaly, the RMS evaluates the event’s priority and decides how to respond, whether to log the information, trigger an alert, modify the robot’s route, or interrupt an ongoing mission.

This operational reasoning and autonomous decision-making capability give RB-WATCHER clear advantages for smarter and more reliable industrial inspection.

Advanced industrial inspection capabilities

Artificial Intelligence enhances RB-WATCHER’s recognition and visual analysis capabilities, enabling it to meet the demanding requirements of industrial inspection, perimeter security, and autonomous surveillance.

The robot integrates multiple computer vision modules, each specifically designed for different inspection and monitoring tasks in industrial environments:

-

- People detection: RB-WATCHER identifies the presence of people in designated areas, automatically generating alerts in the event of unauthorized access or presence in restricted zones. It also incorporates real-time privacy filters that anonymize faces and sensitive data, ensuring compliance with data protection regulations (GDPR).

- Thermal anomaly detection: Equipped with thermographic cameras, RB-WATCHER can detect unusual heat sources or overheating in electrical panels, motors, or industrial installations. It then compares the thermal signal with normal reference values to identify potential fire hazards, short circuits, or heat leaks before they become critical incidents.

- Infrastructure supervision: AI vision also enables the robot to detect vehicles or read license plates within its inspection perimeter, logging events in databases and automatically generating alerts. These capabilities make RB-WATCHER a strategic tool for automating supervision and preventive maintenance tasks, reducing the need for human presence on site.

Extensibility and training of new vision modules

One of RB-WATCHER’s key differentiators is its open and scalable architecture, which allows the development and training of new recognition modules tailored to each client’s specific needs or project requirements.

Examples of extensibility through new detection models include:

-

- Identification of industrial indicators such as pipe leaks, gas emissions, or temperature loss.

- Verification of Personal Protective Equipment (PPE) usage, such as helmets, gloves, or safety boots.

- Recognition of critical components in machinery or industrial facilities.

- Analysis of environmental conditions, such as detecting smoke, gases, or excessive humidity.

AI module development cycle

-

- Data collection: capturing representative images and videos from real environments.

- Data labeling: experts classify images, marking relevant elements.

- Model training: training neural networks using deep learning techniques.

- Validation: testing the model in real conditions to evaluate its accuracy.

- Fine-tuning and continuous improvement: iteratively optimizing the models with new data.

This process ensures that each RB-WATCHER vision module is robust, accurate, and adaptable to diverse operating environments.

Real applications in industrial environments

The combination of AI, computer vision, and autonomous management positions RB-WATCHER as a key tool for Industry 4.0 and advanced security operations. Some examples of practical applications of artificial intelligence in robotics include:

-

- Detecting overheating in electrical panels or motors.

- Identifying unauthorized human presence in restricted zones.

- Monitoring leaks or drips in hydraulic systems.

- Supervising damaged fences, doors, or enclosures.

- Verifying PPE compliance by workers in hazardous areas.

- Monitoring vehicles or misplaced objects within the work perimeter.

Advantages of AI in inspection robotics

The use of Artificial Intelligence in robotics is revolutionizing industrial inspection and security operations. By combining advanced perception and decision-making capabilities, AI empowers robots to operate with greater efficiency and autonomy, offering key benefits such as:

-

- Enhanced autonomy: RB-WATCHER can operate without direct human supervision.

- Risk prevention: early detection prevents incidents and reduces downtime.

- Resource optimization: automates repetitive tasks and frees personnel for higher-value activities.

- Continuous evolution: AI models improve over time through ongoing learning and data updates.

- Interoperability: RB-WATCHER integrates easily with management systems, IoT platforms, and enterprise security solutions.

AI at the service of autonomous inspection

The development of RB-WATCHER reflects the natural evolution of inspection robotics toward systems capable of perceiving, interpreting, and acting autonomously in complex environments.

Its open, scalable architecture allows new AI models to be trained and adapted for various scenarios, overcoming traditional limitations of manual inspection such as subjectivity, fatigue, or restricted access. The combination of multispectral sensors, 3D mapping, and deep learning algorithms places this type of robot at the frontier between automatic observation and intelligent analysis.

Rather than replacing human operators, AI extends their capabilities, taking charge of detection and initial diagnosis tasks while experts interpret the results and validate critical decisions. This hybrid approach marks a shift in paradigm: inspection evolves from a reactive, occasional activity to a continuous, data-driven process supported by constant environmental observation.

The records generated by the system not only document the condition of infrastructures but also feed predictive models capable of anticipating failures and optimizing maintenance. Overall, RB-WATCHER represents a step toward a more autonomous, accurate, and sustainable industrial monitoring model, where infrastructures can be permanently observed through intelligent platforms that learn and evolve with their environment.

Such solutions point to a future in which inspection becomes an integrated part of the life cycle of industrial facilities, continuous, non-intrusive, and far more reliable than traditional methods.

FAQs about AI applied to inspection robotics

The RB-WATCHER’s AI is mainly applied to processing images captured by RGB, thermal, and 3D cameras. Thanks to deep learning algorithms, the robot can recognize objects, people, and anomalies, make autonomous decisions, and continuously improve its accuracy through training with large volumes of real-world data.

The main benefits of AI in inspection robotics include increased operational autonomy, resource optimization and reduction of repetitive tasks, continuous improvement through machine learning, and greater interoperability with other systems and platforms.

The RB-WATCHER is used to detect overheating in electrical equipment, identify unauthorized presence, monitor leaks or drips, inspect fences or damaged structures, and verify the use of protective equipment in high-risk areas.