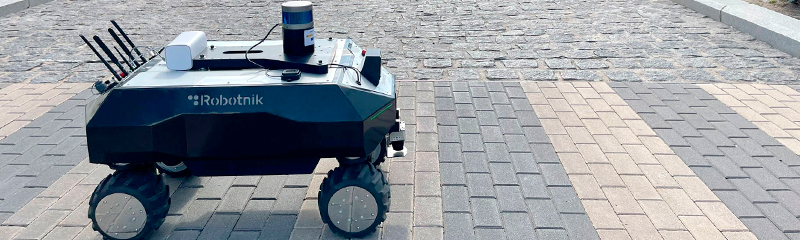

Robotics trends 2024: what will robots be used for?

In 2023, significant changes occurred in the robotics sector, solidifying technologies that undoubtedly expanded the…

2023 in review: robotics trends, technology developments & new robots on the market

2023 has been a year of growth for both Robotnik and the robotics sector in general. In January of this year, Robotnik…

How do AI robots work? Artificial intelligence and mobile robotics

Smarter robots, more autonomous robots, and more useful robots: Robotnik explores some of the most interesting…

The rise of Machine Learning Robots: Explore machine learning in robotics

Among the latest technological advances, artificial intelligence (AI) and machine learning have become increasingly…

What is adaptative robotics?

Adaptive robotics is a field that goes one step further than collaborative robotics. It involves the development and…

What is advanced robotics?

Advanced robotics involves robotic systems capable of taking commands and reacting to them in an intelligent way. For…

Use and applications of Artificial Intelligence in robotics

Bringing together the concepts of robotics and Artificial Intelligence, the first image that comes to mind is that of…