Advanced robotics involves robotic systems capable of taking commands and reacting to them in an intelligent way. For example, a robot that is carrying out a task of transporting material within a warehouse and, upon facing an unexpected obstacle, takes the decision to redefine the optimal route to complete its mission.

In the evolution of advanced robotics, the progress of disruptive technologies such as the Internet of Things (IoT), Big Data, Artificial Intelligence, or cognitive automation, among others, plays a significant role.

These technologies are increasing the capabilities of mobile robots, which now reach higher levels of intelligence and autonomy.

After 20 years of experience in the development of advanced robotics, Robotnik reaches new high demand levels by companies and entities looking for intelligent automation of tasks and processes.

The company, constantly developing robotics R&D, is now seeing how these technologies are transforming the future of manufacturing and driving growth in manufacturing companies and other industries.

Industrial processes used decades ago cannot keep pace with the current exigent, flexible and global demand. In order to adapt production to the context, these exponential technologies are a definite boost. Many factories are already incorporating advanced robotics for warehouse management.

Growth of advanced robotics

Advanced robotics emerged in the 1980s as a term for robots featuring sensorisation and a powerful combination of software and hardware to make intelligent decisions, in contrast to traditional machines.

These types of robots are not limited to the manufacturing environment or Industry 4.0 – although a large part of sales are oriented towards this sector – but are also useful in different industries: construction, health or safety and rescue, for example.

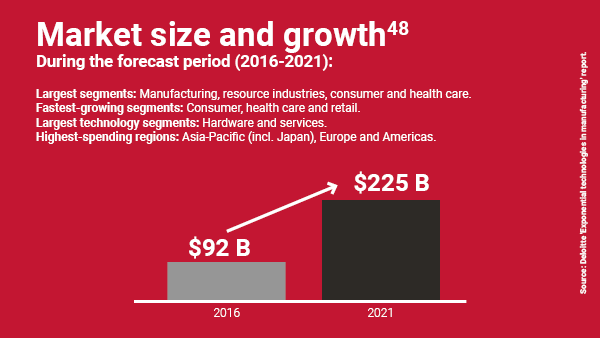

The ability to make decisions autonomously, precision and error reduction or high mobility are some of the characteristics that make the advanced robotics market is moving at high speed, as can be seen in the following table:

Future of advanced robotics

The future of advanced industrial robotics is multi-tasking, collaborative robots, with greater autonomy and increasingly accurate sensing.

Advanced robotics has not yet reached its high point and there are still challenges to be faced. For example, the gap in the technological training of many of the workers in the manufacturing industry or the high cost that some of these technologies represent.

Despite the fact that technological development is constant, Robotnik has the capacity to offer innovative robotics while minimising these problems as much as possible. For example, the fact that Robotnik’s AMRs already integrate 5G technology means a greater guarantee for the Artificial Intelligence, autonomy and safety of the robot.

Advanced robotics: the road to intelligent automation

An important part of intelligent automation is robotics capable of incorporating Artificial Intelligence algorithms. Do you know some of the autonomous, collaborative and mobile robots that are already on the market?

Here are some examples of advanced robotics from Robotnik:

Gear factory: The Netherlands company Hankamp Gears BV incorporates robotics to perform pick and place and handling tasks in the production line of metal gears.

Security and rescue sector: Here you can read about robots that, through high sensorization, are able to support security personnel in emergency situations.

Logistics: Part of the result of the PILOTOS 5G project was two demonstrations in large industrial plants in which Robotnik’s mobile robot RB-VOGUI has autonomously and collaboratively carried out logistics tasks in the transport and supply of materials.