One of the most robotics trends in industry is the customization of robots to meet specific manufacturing needs.

Industries demand flexible solutions that adapt to particular requirements or operational environments where standardized robots fall short.

This has driven the development of custom industrial manipulators, designed to integrate efficiently into dynamic production environments.

This article addresses several relevant viewpoints on robot customization for specific applications: trends, modularity options, advantages, and examples of modularity.

WHEN TO CHOOSE A CUSTOMIZED ROBOT FOR MY INDUSTRY?

A robot with customization or modularity options can be the ideal solution when standard commercial models do not meet the specific requirements of an industrial application. This flexibility is a distinctive feature of manufacturers like Robotnik. Our mobile robots are fully developed by our team, both in software and hardware, which allows us to adapt certain functionalities based on each client’s needs.

Users value customizable robots in cases such as:

- Reduced workspace or physical restrictions: In environments where space is limited or machinery layout makes the installation of conventional robots difficult, a modular robot allows for more efficient integration and better performance. For example, in a production plant with narrow aisles, a mobile robot with a compact base and the ability to incorporate additional sensors or components adapted to the application and available space optimizes operability without compromising efficiency.

- Development of customized industrial applications: In industries such as retail, highly specialized applications requiring effective hardware and software integration are common. An example of customization for developing specific applications is the collaboration between Keonn and Robotnik, resulting in the Robin robot. It is the outcome of development based on the RB-THERON mobile base, integrated with Keonn's software that enables automatic RFID tag reading to optimize inventory management in retail, providing fast and accurate inventory scanning without manual intervention.

- Research and Development (R&D): In companies with R&D departments, tech centers, or academic institutions, modular robots offer a significant advantage by enabling researchers to design highly customized solutions for specific projects. These environments often work on developing new technologies, innovative processes, or improving existing ones, which frequently require fine adjustments to both the robot’s hardware and software. The modularity of these systems allows R&D teams to adapt individual components such as arms, sensors, tools, or control systems based on each project's requirements, without the need to acquire a completely new robot. This flexibility speeds up the trial-and-error process, enabling rapid iterations in design, implementation, and optimization. Additionally, customizing modular robots facilitates experimentation with new configurations, tools, or algorithms, which is essential in developing emerging technologies such as artificial intelligence, collaborative robotics, or advanced automation.

BENEFITS OF CUSTOMIZABLE ROBOTS

Customizable robots offer a range of key benefits that make them an attractive option for various industries. First, the level of modularity allows adaptation to specific implementation needs. Additionally, by offering flexibility in both hardware and software, they can easily integrate into changing production environments, facilitating automation without significant economic investment. They also allow for greater scalability, as they can be modified or expanded to meet future demands or production requirements. Finally, by being aligned with the exact needs of an industry, customizable robots contribute to greater competitiveness and long-term cost reduction:

- Increased productivity: Reduced cycle times and increased production.

- Adaptability to different industries: From automotive to electronics, customized robots can adjust to various applications.

- Enhanced safety: Reduced workplace risks by minimizing human intervention in hazardous tasks.

- Quick Return on Investment (ROI): Long-term savings in operational costs.

EXAMPLES OF MODULAR ROBOTS

Modular robots can adapt at certain levels to meet specific needs across different industries, providing tailored solutions that optimize efficiency, safety, and productivity. At Robotnik, we have experience in customizable robotics projects ranging from hardware modifications or mechanical changes to increase payload or reach greater heights in mobile manipulators, to software adaptations to provide robots with specific functionalities based on application requirements. Here are 3 examples of Robotnik robots adapted for different tasks:

- RB-VOGUI XL: This version developed from the RB-VOGUI has an increased payload capacity, able to transport materials of up to 200 kg for outdoor applications in areas such as agriculture or construction.

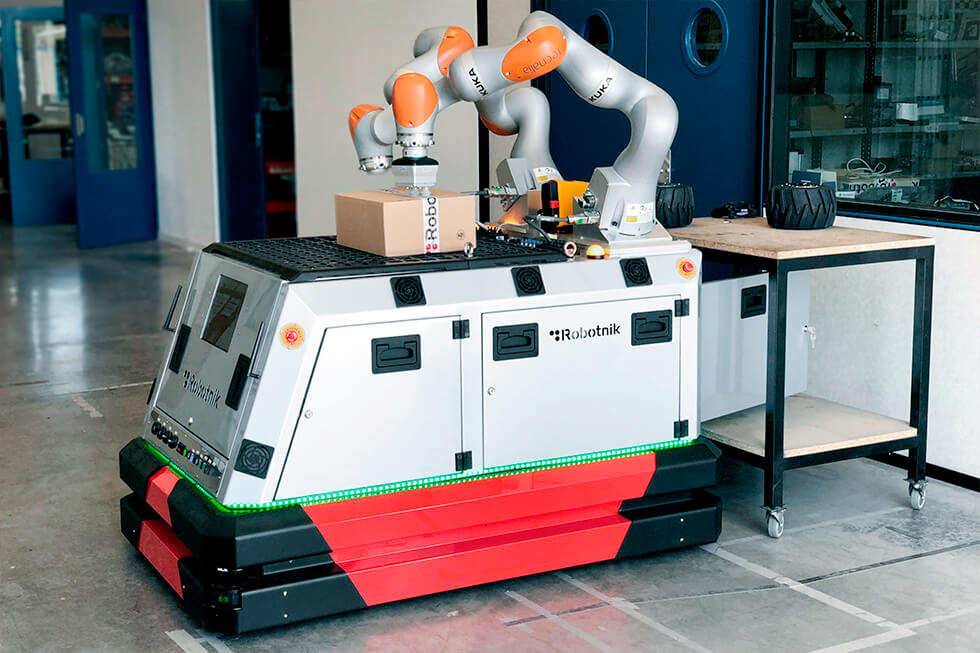

- RB-ROBOUT+ DUAL: The key features of this mobile manipulator, developed together with Tecnalia, are its bimanual manipulation capability, combining two 7-DoF collaborative arms with high payload capacity, integrated into an omnidirectional mobile base.

- ROBIN: The robot for retail applications developed by Keonn from Robotnik's AMR RB-THERON. Robin automatically performs inventory checks for a specific space, such as a retail store or warehouse, providing greater RFID inventory accuracy than handheld and manual readers.

TRENDS IN ROBOT CUSTOMIZATION FOR INDUSTRIAL APPLICATIONS

Customizable robots offer a range of key benefits that make them an attractive option for various industries. First, the level of modularity allows adaptation to specific implementation needs. Additionally, by offering flexibility in both hardware and software, they can easily integrate into changing production environments, facilitating automation without significant economic investment. They also allow for greater scalability, as they can be modified or expanded to meet future demands or production requirements. Finally, by being aligned with the exact needs of an industry, customizable robots contribute to greater competitiveness and long-term cost reduction:

- Modularity and Flexibility: Modular robots, such as the use of mobile bases and interchangeable components, allow companies to adapt their solutions to different tasks and operating conditions. This facilitates updating and expanding capabilities as industry needs change.

- Integration with advanced technologies: Customizing robots for industrial applications increasingly includes the integration of technologies such as RFID, computer vision, components, or AI to improve autonomy, precision, and adaptability in complex environments.

- Open and adaptable software interface: Robotnik's robots allow for deeper software customization, with platforms that facilitate integration with existing company systems and simplify the development of specific applications for particular tasks.

- Autonomy and advanced navigation: Advances in autonomous navigation allow robots to adapt to changing environments, avoid obstacles in real-time, and optimize routes. This is particularly valuable in industrial applications where space and work dynamics are variable.

- Scalability: As companies grow, the need to scale automation is crucial. Customizable robots allow fleets of units to be expanded with features and capabilities tailored to new demands without affecting the overall system’s performance.

- Collaborative interaction (Cobots): The trend toward collaborative robots is on the rise, with robots capable of working safely and efficiently alongside operators. Customization in these robots includes adapting payload capabilities, safety sensors, and interaction modes to maximize operational efficiency in a shared workspace.

The customization of industrial robots represents a revolution in manufacturing, enabling the optimization of efficiency, quality improvement, and greater flexibility in production lines. From customized industrial manipulators to innovative mobile robotics solutions, companies can benefit from the adaptability and technological improvements these systems offer. Investing in robot customization is a key strategy to remain competitive in Industry 4.0.