Logistics automation for warehouse operations has become a key factor for efficiency in an increasingly competitive production environment. The technological advancement of mobile robots makes the warehouse operations optimization more accessible than ever for companies of any size.

This article reviews some of the global data from the latest report from the IFR – International Federation of Robotics which shows that logistics remains one of the top 5 areas for service robotics applications.

STAFF SHORTAGES DRIVE SERVICE ROBOTS: SALES UP 48%

‘The total number of service robots sold for professional use reached 158,000 units in 2022, an increase of 48%. Staffing shortages are a strong push for companies to automate.” World Robotics, October 2023.

The International Federation of Robotics (IFR) ‘World Robotics 2023’ report compares the adoption of robots in various industries and the type of applications to the previous year, highlighting a significant increase in sales of service robots.

Sales of service robots increased by 48% in the last year, an extraordinary growth that is largely due to staffing shortages in many industries. This has led companies to look for automated solutions that meet the needs of skilled labor for certain applications, such as warehouse operations.

TOP 5 APPS IN SERVICE ROBOT SALES IN 2022

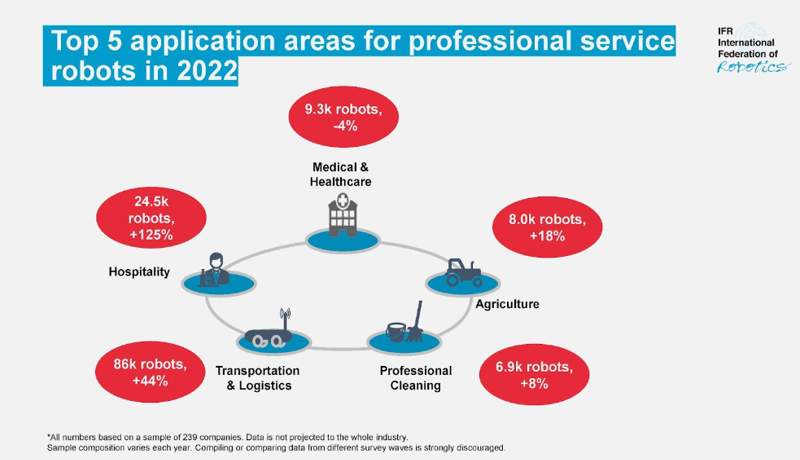

The figure above shows how mobile robotics solutions in the transport and logistics sector have consolidated their position in the market. The implementation of robots for the transport of goods and the optimisation of warehouse operations in general surpasses any other application in terms of market share. During the year 2022, sales experienced a growth of 44%, with a total of more than 86,000 units sold. Specifically, a 78% increase in sales of robots designed to operate in collaborative indoor environments was highlighted, reaching nearly 37,300 units.

Robots geared towards the hospitality industry are gaining increasing popularity. In 2022, more than 24,500 units were sold, an increase of 125%. Many of these robots are intended for the delivery of food and beverages in restaurants.

In the field of medical robotics, sales saw a 4% decline, reaching approximately 9,300 units. Despite this downward trend, nearly 4,900 surgical robots were marketed, an increase of 5%. However, sales of robots intended for rehabilitation and non-invasive therapy applications declined 16% to less than 3,200 units.

Robotics applied to agriculture saw a growth of 18%, with a total of almost 8,000 units sold while the use of professional cleaning robots saw a growth of 8%, reaching almost 6,900 units sold.

While the IFR report focuses on service robot sales in general, it focuses specifically on warehouse operations and logistics automation, where mobile robots such as RB-THERON or RB-ROBOUT play an important role.

LOGISTICS AUTOMATION: PROVEN EFFICIENCY

Logistics and warehouse management are important issues in any company’s supply chain. Efficiency in warehouse operations not only reduces costs, but also improves customer satisfaction by ensuring fast and accurate deliveries. In this context, the automation made possible by mobile robots has become a valuable tool.

Logistics automation encompasses a wide range of technologies, including software for warehouse management, automated conveyor systems, or mobile robots. These robots are capable of performing a variety of tasks in logistics environments such as transporting goods to organizing inventory.

Autonomous mobile robots work in collaborative environments consistently without fatigue, minimizing errors, saving costs, and increasing the productivity of a warehouse.

INCREASE PRODUCTIVITY IN THE WAREHOUSE

Warehouse productivity comes into greater responsiveness to market demands, shorter delivery times, and lower operating costs. The growth observed in the IFR report on the logistics and transport sector, verifies the value that mobile robots bring to achieve these goals. Route optimization, efficient inventory management, and speeding up picking and packing processes are key for companies looking to stay competitive in the market.

- Route Optimization

One of the challenges in warehouse operations is ensuring that goods move efficiently from the point of receipt to the point of shipment. Mobile robots can calculate and follow optimal routes, minimizing travel time, avoiding dynamic obstacles, and reducing congestion in the warehouse.

This route optimization not only increases the speed of delivery, but also reduces wear and tear on facilities and equipment, saving costs in the short and medium term. - Accurate Inventory Management

Accuracy in inventory management is essential to any logistics operation. Mobile robots are equipped with sensors and vision and recognition systems that allow them to constantly track inventory. This ensures that goods are sorted or stored where they belong.

Additionally, the ability to track inventory in real-time helps prevent losses and ensures that goods are available when needed. This is especially important in a business environment where demand can be unpredictable. - Picking and Packing Efficiency

Picking and packing products or goods are the critical warehouse operations that waste the most workers’ time. Mobile robots speed up this process by bringing products to workers instead of looking for them on the shelves. These collaborative robots can work safely with employees, allowing for greater flexibility in allocating resources based on changing needs. - Adaptability to demand

Another factor that considerably affects the productivity of a warehouse is the fluctuation in demand, which can vary significantly depending on various factors such as seasonality, socio-political circumstances or simply consumer trends. Mobile robots have an advantage over robots that are installed (fixed) in a single location or developed to perform a single type of task. They are highly adaptable and can perform different tasks in one or multiple locations. - Error Reduction

Errors in warehouse operations cost a company time, money, and resources. The precision and sensorization of the RB-KAIROS+ Mobile Manipulator robot reduces failures in tasks such as Pick & Place to a minimum, creating reliable workflows. Here you can find a real use case of the manipulator robot deployed in a gear factory.

CONCLUSION

Mobile robots have become powerful tools for optimizing warehouse operations and increasing productivity. With growing staffing shortages, companies are looking for solutions that allow them to stay efficient and competitive. Mobile robots not only improve efficiency, but also reduce operating costs and errors, resulting in higher customer satisfaction.

The value that AMRs bring to logistics automation is reflected in the IFR’s recent report ‘World Robotics 2023’, which highlights the growing adoption of service robots for transport and logistics.

Warehouse automation through mobile robots improves supply chain management thanks to its ability to optimize routes, manage inventories, increase picking and packaging efficiency, adapt to demand, and reduce errors, making it a smart investment for companies to stay competitive in the global market.

Want to know more about logistics in warehouses?