In robotics, the Human-Machine Interface (HMI) is the control interface that facilitates communication between the user and the robotic system through devices such as tablets, PCs, or smartphones. Through the HMI, operators can monitor the robot’s status, configure parameters, execute tasks, or analyze data in real time, significantly improving the operability, safety, and usability of robotic systems. The HMI becomes even more important in industrial, logistics, inspection, or surveillance environments, where intuitive interaction and precise control are essential for effective automation.

To further enhance user interaction, Robotnik has developed a new Human-Machine Interface for the RB-WATCHER surveillance robot.

This tool is designed to improve communication between the operator and the robot, simplifying complex tasks such as route configuration, mission management, remote teleoperation, and receiving alerts or notifications via email or Telegram in case of anomalies in the environment.

This article explains the benefits this interface offers for smarter, more autonomous surveillance.

WHAT IS HUMAN-MACHINE INTERFACE (HMI) IN ROBOTICS?

In general terms, an HMI is a software and hardware development that allows users to communicate and interact with a machine without needing to modify its code. There are many examples of HMI in everyday life, ranging from mobile apps used to control home cleaning robots to voice-based virtual assistants managing smart home systems.

Beyond these commercial uses, HMI in robotics enables users of different skill levels to monitor robot status, control movement, define behaviors, analyze operational data, and manage automated tasks.

Depending on the application (industrial, logistics, medical, surveillance, etc.), HMIs may range from simple data displays to complex platforms featuring interactive dashboards, real-time maps, and mission scheduling.

In the case of RB-WATCHER, the HMI serves as the user interface that optimizes control, monitoring, and programming of the robot, enabling more intuitive operation.

Users can access the HMI from any web browser connected to the same network as the robot and follow the steps outlined in the Control Interface Manual to log in and perform the initial setup. From that point, the user has access to the various panels, navigation pages, and available functionalities.

Robotnik has enhanced the user interface so that both basic operators and expert developers can manage complex tasks—from defining patrol zones to analyzing real-time data.

KEY FEATURES OF THE RB-WATCHER HMI

The new Human-Machine Interface (HMI) for the RB-WATCHER robot has been developed with a user-centered focus, delivering maximum simplicity. The result is faster robot management and better operational control, making it easier than ever to work with autonomous systems in real-world environments.

1. Map Creation and Definition of Areas of Interest

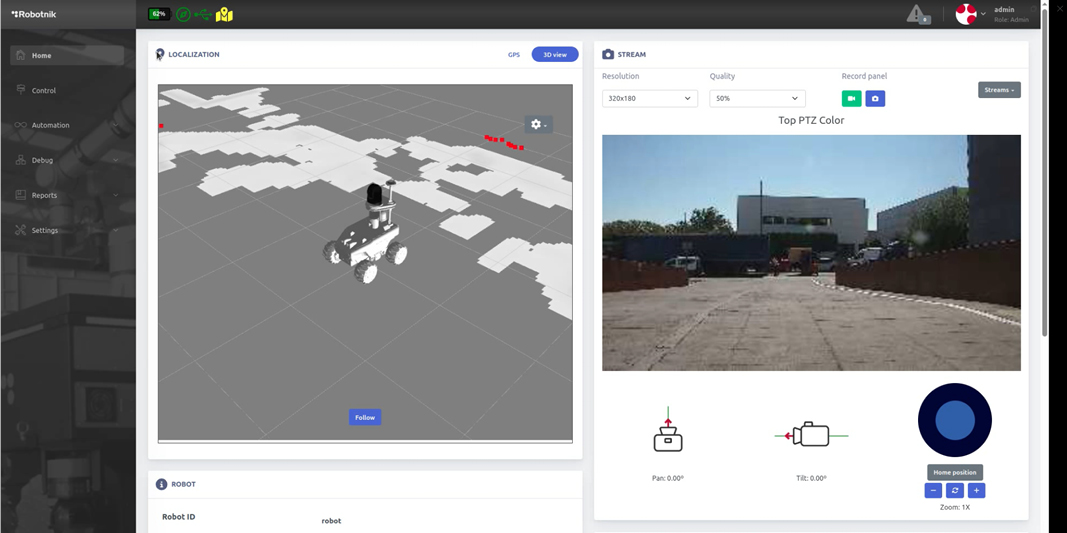

One of the most important features of the RB-WATCHER’s HMI is the ability to create customized maps and define specific operational areas and points of interest using precise coordinates. This functionality is essential for the robot’s autonomous navigation in both indoor and outdoor environments.

The robot can travel efficiently to predefined locations, optimizing patrol routes and ensuring complete coverage of strategic zones—a critical requirement for smart security and surveillance missions.

2. Automated Task Scheduling and Patrol Planning

The HMI includes an advanced task scheduler that enables users to program routes, periodic inspections, and specific actions based on predefined times or dates.

This feature facilitates more autonomous operation of the RB-WATCHER, reducing the need for manual supervision. The system also allows easy adjustment of plans in response to changing operational conditions or requirements.

3. Real-Time Monitoring and Data Analysis

The real-time monitoring system integrated into the HMI offers a comprehensive view of the robot’s status and performance. Through charts, metrics, and historical logs, operators can analyze robot behavior, detect potential issues, and optimize future missions.

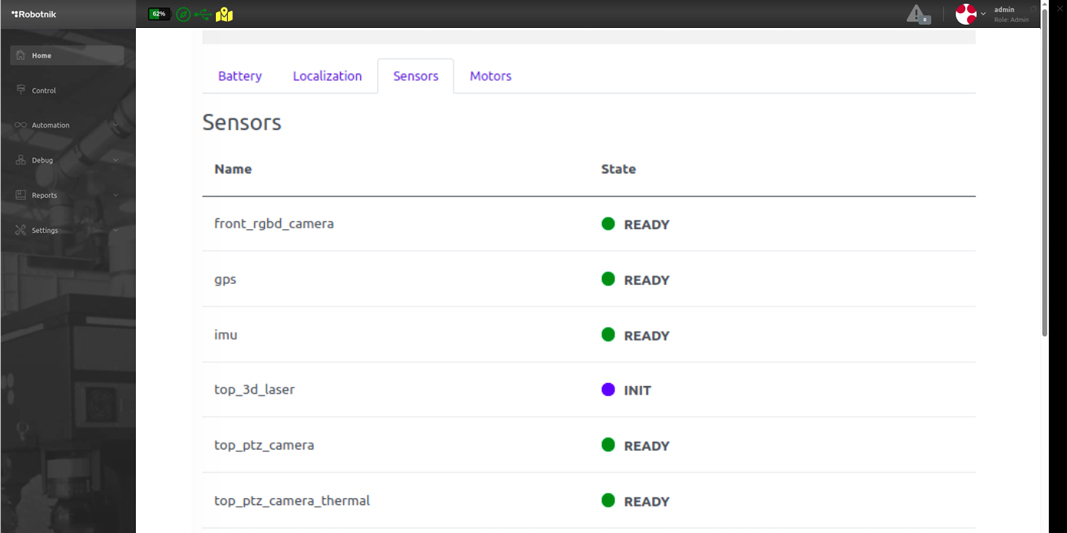

In addition, the HMI provides oversight of critical variables such as battery level, speed, and sensor status—vital information for ensuring the safety and effectiveness of operations.

4. Remote Teleoperation with Camera Access

A standout feature of the RB-WATCHER’s HMI is real-time remote teleoperation. This enables manual operation of the robot from any location, such as a central control room.

Teleoperation is conducted securely from a remote workstation, with direct visual feedback via the robot’s integrated cameras. This enables fast and accurate decision-making in critical scenarios such as unfamiliar environments, detailed inspections, or unforeseen events.

5. User Role Management and Access Control

To ensure secure and efficient use, the HMI includes a role-based access control system that adapts to different organizational roles. This allows configuration of access privileges and the functionalities each user can manage based on their responsibility level:

- Read-only (Monitoring): Access to view information without modification permissions.

- Overview, Control & Teleoperation: Enables monitoring and manual control when required.

- Edit Permissions: Allows configuration of maps, tasks, and operational parameters.

- Developer (DEBUG): Access to advanced functions for development and specific adjustments.

- Super Administrator: Full control including complete automation, mission management, and system configuration.

BENEFITS OF HMI FOR AUTONOMOUS SECURITY AND INSPECTION

Implementing the HMI in the RB-WATCHER offers multiple benefits for companies and public agencies requiring continuous, automated surveillance:

- Greater Operational Efficiency: Smart automation and scheduling reduce manual intervention and improve coverage.

- Improved Decision-Making: Real-time data analysis enables proactive issue detection and mission optimization.

- Flexibility and Adaptability: Customizable maps, routes, and tasks allow seamless adaptation to different environments and needs.

- Enhanced Security: Role-based access control and remote teleoperation ensure safe and responsible robot use

- Scalability: The system supports different user levels, from basic operators to advanced technicians.

THE FUTURE OF HMI IN ROBOTICS

The evolution of Human-Machine Interfaces in robotics is closely tied to emerging technologies such as artificial intelligence, edge computing, augmented reality, and multimodal interfaces. The near future will see systems capable of understanding their operational context, adapting dynamically to user profiles, and offering more predictive than reactive supervision and control.

The integration of AI models into HMI platforms will not only enhance decision-making for operators but also automate complex processes through streamlined interfaces. At the same time, 5G connectivity and cloud computing will enable HMIs to be more distributed and accessible in real time from anywhere.

These advancements establish the HMI not merely as a bridge between humans and machines, but as a critical abstraction and coordination layer between heterogeneous systems—essential for scaling autonomous robotics in industrial, logistics, urban, or security environments.

The new HMI for the RB-WATCHER represents a significant step forward in human-machine interfaces for autonomous surveillance robots. Its combination of advanced features and ease of use enhances operational control, improves safety, and boosts robot autonomy.

Contact Robotnik to explore how this innovative HMI can improve your robotic workflows, mission planning, and operational control.

Preguntas frecuentes sobre la róbotica en la industria aeroespacial

Los robots móviles realizan tareas de alta precisión como inspecciones dimensionales, tratamientos de superficie y ensamblaje de componentes, garantizando calidad y seguridad.

Mejoran la repetibilidad, ahorran tiempo, no requieren de modificaciones en la planta y aumentan la seguridad gracias a la colaboración humano-robot.

Utilizan sistemas de escaneo 2D/3D para moverse de forma autónoma sin marcas en el suelo ni guías físicas.