After a very successful reading of the ‘Complete guide to robot manipulators: advantages and applications’, here we provide the answers to the top 50 questions asked about mobile robot manipulators.

Mobile manipulators are becoming increasingly important in industrial settings, providing a unique combination of mobility and precision. These robots are now used in industries ranging from manufacturing to agriculture, thanks to their ability to automate complex tasks. In this article, we answer 50 frequently asked questions about mobile manipulators, covering topics such as collaborative robotics, hazardous environments, precision engineering, and programming robot manipulators for optimal performance.

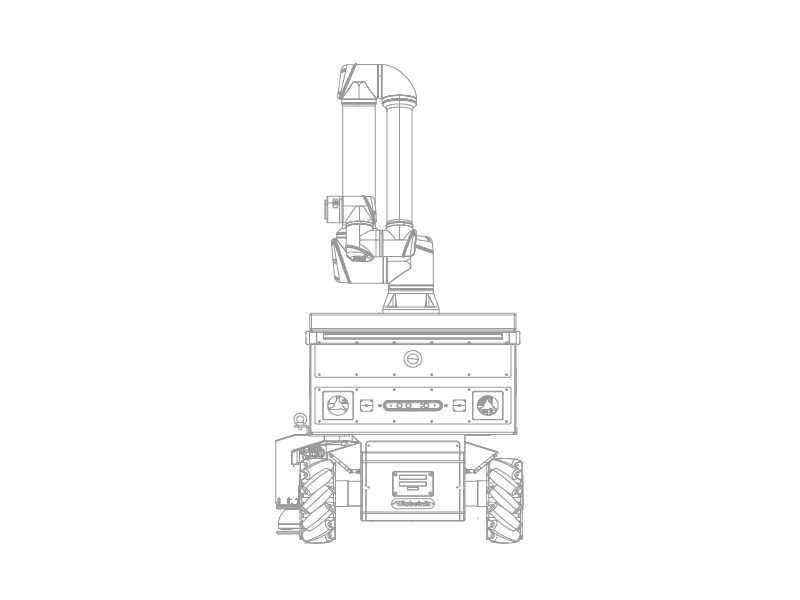

1. What are mobile manipulation robots?

A mobile manipulator robot is the one that combines the capabilities of a mobile robotic platform (moving through multiple locations) and a manipulator arm (object manipulation). These robots have the ability to move in their environment while performing tasks such as grasping, moving, and handling objects.

2. What are the applications of mobile manipulation robots?

Mobile manipulators have applications in various industries such as logistics, manufacturing, agriculture, inspection or the healthcare sector. They are especially useful for automating repetitive or hazardous tasks such as loading and unloading materials, assembly, handling toxic substances, or harvesting agricultural products.

3. How do mobile manipulation robots differ from traditional industrial robots?

Industrial robots are typically fixed in a single location and perform repetitive tasks in a controlled environment. Mobile manipulators, on the other hand, can move freely to perform tasks at different points in a dynamic environment.

4. What are the latest use cases for mobile manipulator robots in agriculture?

Mobile manipulator robots in agriculture are used for automatic fruit and vegetable harvesting, plant pruning, sowing or crop monitoring. These robots are optimized to work in outdoor conditions and adapt to uneven terrain.

5. What advances exist in human-robot interaction for mobile manipulator robots?

Advances in Robotnik’s mobile manipulators include more intuitive interfaces, sensors for even safer collaboration in shared environments, and Artificial Intelligence algorithms that allow them to better understand both people and the environment and make smarter decisions.

6. How can mobile manipulator robots be optimized for greater energy efficiency?

For example, through the use of high-performance batteries, more efficient path planning algorithms and power saving modes when not active. Hardware designs with low-power motors and advanced controllers also contribute in this regard.

7. What components are part of a mobile manipulator robot?

The two basic parts are a mobile platform and a robotic arm. In addition, there is a wide variety of final tools available to attach to the arm, depending on the needs of the task: grippers, suction cups, robotic hand, screwdriver, vision tools…

8. What type of sensors do mobile manipulators use?

They use cameras RGBD, 3D LiDAR, ultrasound, GPS, IMU or force/torque sensors to detect objects, map their environment and calculate the force needed to manipulate objects.

9. Are mobile manipulator robots safe to work alongside humans?

Robotnik’s mobile manipulators are safe. They are equipped with safety systems, sensors and advanced collision detection and avoidance algorithms to ensure safety in collaborative environments shared with humans.

10. What software do mobile manipulator robots use?

Mobile manipulators typically use ROS (Robot Operating System), an open-source framework that allows integration of sensors, actuators, and complex algorithms, making it the go-to solution for mobile robotics.

11. What advantages do mobile manipulator robots have compared to fixed robots?

The main advantage of these robots is flexibility and scalability. They can move over large areas and reconfigure to perform multiple tasks according to the need of the moment, without major modifications to the layout. It is not necessary to modify the infrastructure through which these robots will move, so scaling the number of units is easier.

12. What is the typical battery life of a manipulator mobile robot?

Duration varies depending on use and the type of battery included, but, on average, it can last between 6 and 10 hours on a single charge.

13. Can mobile manipulator robots work outdoors?

It depends on the model. RB-VOGUI+ or RB-SUMMIT+ are some of the manipulator robots that can operate outdoors, even in variable environmental conditions such as wind, rain or uneven terrain.

14. What industries benefit the most from the use of these robots?

Historically, the industries with the greatest use of manipulator robots are logistics, manufacturing, automotive, and the chemical/pharmaceutical industry. But the agricultural and construction sectors have considerably increased their use in recent years.

15. What is the cost of a mobile manipulator robot?

The cost varies depending on the features and capabilities of the robot, generally, the market price ranges between 50,000 and 150,000 euros, depending on the model and level of customization.

16. How does the use of mobile manipulator robots improve productivity?

A mobile manipulator improves productivity due to its ability to work in shifts 24/7, improving productive times, avoiding repetitive tasks for workers and reducing the rate of errors/failures in the processes.

17. What level of autonomy do these robots have?

They can operate fully autonomously or semi-autonomously, depending on tasks and system configuration. They can make decisions in real time based on data from their sensors or execute the missions of an operator who is managing it remotely.

18. How long does it take to install a mobile manipulator robot in an industrial environment?

Installation can take from a few days to several weeks, depending on the complexity of the environment and application.

19. What advances are expected in autonomous mobile manipulation in the coming years?

One of the main challenges in the mobile robotics sector is to advance in autonomous navigation issues. We have overcome important barriers in that area but there is still room for improvement. We are also working to equip our robots with greater capacity for human-robot interaction and algorithms for more complex manipulation tasks.

20. Can manipulative mobile robots collaborate with each other?

Yes, many are designed to work collaboratively with other robots, sharing information to optimize tasks and interact according to each one’s capabilities.

21. What is autonomous mobile manipulation?

Autonomous mobile manipulation refers to a robot’s ability to move and manipulate objects without human intervention, using AI, sensors, and algorithms to make decisions in real time.

22. How does sensor quality affect robot performance?

High quality sensors provide more accurate data, improve navigation and handling accuracy. Poor sensors can lead to errors and task failures. Therefore, the low price of a robot should not always be the deciding factor for the user. The cost of a robot includes, for example, the quality of the sensing it incorporates.

23. What role does artificial intelligence play in these robots?

Artificial Intelligence in robotics is used, for example, for object recognition, trajectory planning and decision making in real time.

24. Can mobile manipulator robots learn new tasks?

Yes, they can be relatively easily reprogrammed or trained to learn new tasks through Deep Learning techniques.

25. Is it difficult to set up a mobile manipulator robot?

Not necessarily. There are intuitive programming interfaces that simplify configuration and scheduling of tasks. However, programming certain types of complex tasks may require more advanced knowledge. In any case, the Robotnik team offers advice according to needs.

26. What types of objects can these robots manipulate?

They can manipulate a large number of objects of different sizes, shapes and textures. From small parts on assembly lines, screws, washers, electronic components or test tubes to 20 kg boxes in warehouses.

27. What are the key features I should look for when purchasing a manipulator mobile robot?

Always evaluate the load capacity of the arm and platform, the reach of the arm, the battery life, the type of sensors and the reliability offered by the manufacturer.

28. How is precision in object manipulation ensured?

The precision of the robotic arm is influenced by force sensors, advanced vision and precise control algorithms that adjust the robot’s position and grip in real time.

29. How are mobile manipulation robots integrated into existing manufacturing systems?

They integrate making the necessary adaptations to the plant layout, connecting to management systems (MES/ERP) and coordinating them with other equipment using automation software.

30. What technical challenges does autonomous mobile manipulation face?

Challenges include manipulating irregular objects, navigating unstructured environments, and optimizing energy usage to extend operational time.

31. Can these robots operate in multi-level warehouses?

Yes, certain models can navigate multi-level environments using ramps or elevators, allowing them to operate efficiently in complex warehouse layouts.

32. Can mobile manipulator robots be customized?

Yes, manufacturers like Robotnik offer custom hardware and software adaptations to meet specific industry needs, ensuring that robots can perform specialized tasks, depending on the specific needs of the client.

33. Is it possible to rent a mobile manipulator robot?

Yes, some suppliers offer the option to rent robots for short-term projects or for testing before making a purchase. This is known as Robot as a Service – RaaS.

34. What skills must an operator have to operate a mobile manipulator robot?

One of the biggest advantages of collaborative robotics is that it is not essential for the operator to have a great knowledge in programming or robotics. The Advanced User Interface makes it very easy to operate and control the robot.

35. What is the useful life of a manipulator mobile robot?

The useful life of a mobile manipulator robot generally varies between 5 and 15 years, depending on use, maintenance and operating conditions.

36. How do these robots impact workplace safety?

They improve safety by taking on tasks that are dangerous to humans, such as moving heavy loads or working in unhealthy, toxic, or difficult-to-access environments.

37. Can mobile manipulator robots work in different industries simultaneously?

Yes, a single mobile manipulator robot can work in different industries due to its ability to adapt to different tasks and environments. Their versatility allows them to perform everything from assembly in manufacturing to logistics in warehouses. Their flexible programming and ability to change tools makes them useful in multiple industries.

38. What is the future of mobile manipulator robots?

Advances in mobile manipulation robotics are oriented towards greater autonomous intelligence, greater human-robot interaction and the ability to perform increasingly complex tasks. We are also working so that our robots can be deployed in more and more types of environments, both indoors and outdoors.

39. What type of navigation system do mobile manipulator robots use?

They use navigation based on SLAM (Simultaneous Localization and Mapping) and technologies such as LiDAR, GPS and AI to detect obstacles, optimize routes and adapt to changes in the environment in real time.

40. Can mobile manipulator robots work 24/7?

Yes, with proper configuration and maintenance, they can operate continuously, except for the battery charging time that each model requires.

41. How does the working environment affect the performance of the robot?

The type of environment affects the accuracy of the sensors and the maneuverability of the robot. For example, uneven or poorly lit terrain can make navigation and manipulation difficult, if the robot itself has not been designed to operate in those specific conditions. Both the sensorization included and the IP determined by the manufacturer must be taken into account.

42. Is it possible to control a mobile manipulator robot remotely?

Yes, it is possible and, in fact, a widely used option for applications related to inspection and maintenance, for example. In these cases, remote control is executed via desktop applications or software.

43. What level of precision can these robots achieve when manipulating objects?

Accuracy or repeatability varies by model, but many can operate with millimeter precision. The cobots from Universal Robots, for example, range from ±0.03 mm. or ±0.05 mm.

44. How can manipulative mobile robots be integrated into Industry 4.0?

They integrate into Industry 4.0 by connecting with cyber-physical systems, IoT, and data networks in real time, allowing them to collaborate with other smart devices.

45. What is the impact of mobile manipulation robots on sustainability?

They contribute to sustainability by optimizing the use of resources, reducing waste derived from manufacturing errors and providing certain improvements related to the sustainability of industrial processes. Here we explain more about robotics and sustainability.

46. How is robotics used in precision tasks?

Manipulation robotics allow operations that require high accuracy in areas such as surgery, assembly and advanced manufacturing.

47. What are manipulators used for in hazardous environments?

A manipulator robot is especially useful in tasks that involve risks for operators, such as those that take place in chemical plants or radioactive areas.

48. What are collaborative manipulator robots?

They are robotic arms or mobile manipulators designed to work safely alongside humans, automating repetitive or high-precision tasks in collaborative environments.

49. What industries benefit from robotics?

Sectors such as automotive, medicine, electronics and manufacturing are some of those that use manipulation robotics the most to improve efficiency and precision in their processes.

50. What languages are used to program manipulator robots?

Languages such as ROS, Python or C++ are the most widespread for robotics programming. In this article we go into more depth about each of them, their advantages and characteristics.