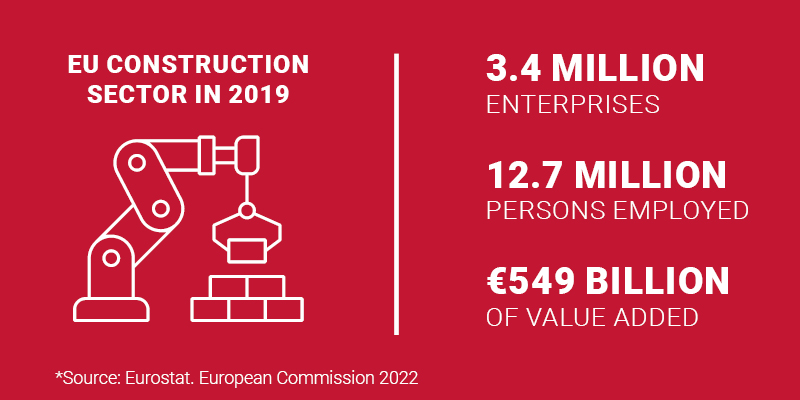

According to the statistics provided by the European Commission for 2022, through the official statistics agency Eurostat, the construction sector in Europe is made up of 3.4 million companies, has 12.7 million people employed and has an added value of 549 billion euros.

Construction is a strategically important sector involving various stakeholders and companies, playing a key role in any country’s economy. However, the construction sector is one of the most unstructured and has made the least progress in the last century, from a technological perspective. One of the main barriers presented by this sector is the complexity of integrating all the parties involved in a construction project along with the available technological systems and the multiple processes and workflows in place. The lack of interoperability between all parties and the need for specialized personnel for integration pose a major challenge, especially in the context of Construction Sector Digitization and Robotics and BIM Integration.

The ECSO (European Construction Sector Observatory) states in the Report on digitalization in the construction sector that ‘The integration of digital technologies is a key element to overcome the biggest obstacles in the construction sector, such as labour shortages, competitiveness, energy and resource efficiency, and productivity’. To achieve the desired level of automation, analogous to Industry 4.0, cutting-edge technologies such as Augmented Reality Construction Tools, high-performance computing, additive manufacturing, advanced materials, autonomous robots, simulation systems, or BIM (Building Information Modeling), a collaborative work methodology for the creation and management of a construction project, have been adapted to construction applications. This Digital Transformation in Construction and automation of the sector has been called Construction 4.0.

The evolution of these technologies applied to the construction industry brings benefits by automating traditionally manual, laborious, repetitive, and even risky construction tasks for workers, such as the use of Mobile Robots for Construction and Inspection Robots in Building.

Robotnik has been part of a consortium of 12 partners who have been working for 3 years on BIMprove, a project funded by the European Union within the framework of the Horizon 2020 program. The aim has been to boost Europe’s stagnating construction sector and to address long-standing problems such as declining productivity, hazardous environments for workers, negative environmental impact, and the failure to match the budget to actual costs.

In this interview, Miquel Cantero, Project Manager at Robotnik, talks about the milestones reached in BIMprove, the main developments, the challenges they faced, and what autonomous mobile robotics brings to the current construction sector.

Miquel Cantero interview

At BIMprove we have focused on addressing several challenges that affect the construction sector and that prevent work in this area from improving qualitatively. Probably one of the main reasons for the lack of workforce in this sector is that it continues to be one of the most hazardous and unsafe sectors for workers.

The development of a dynamic digital system for construction sites, such as incorporating Digital Twin in Construction, is a solution that not only accelerates productivity but also reduces costs and improves working conditions. Specifically, we have expanded the available Building Information Modelling (BIM) systems by incorporating Digital Twin technology. This innovative approach introduces a much more dynamic and multifunctional procedure, by merging Artificial Intelligence with technologies such as AR/VR in construction projects, autonomous mobile robotics, and wearable devices.

The project’s SUMMIT-XL has been adapted to perform mainly Inspection and Maintenance tasks related to data acquisition on the construction site. The introduction of mobile robotics in this context represents a significant boost in the ability to collect information remotely, constantly, reliably, and autonomously, overcoming the limitations of traditional manual methods.

The robot is capable of collecting different critical data including point clouds, high-quality geolocated images and photos, as well as thermal photos for the detection of possible hot spots during inspection work. To ensure accuracy in data acquisition, we have integrated Reality Capture technology with Leica GeoSystems, which provides millimeter accuracy for point clouds. Accuracy is essential in a construction process, which starts with basic data capture, being the initial step necessary for the creation of 3D models and, subsequently, IFC (Industry Foundation Classes) models that represent both the planned state and the built state (as planned/as built).

Sure, an example of how the SUMMIT-XL could be useful in a real use case would be the validation of the execution of the vertical walls of a basement under construction. A SUMMIT-XL is incorporated to carry out data capture autonomously in the area of interest, in this case, the vertical walls of the basement.

After collecting point clouds, high-quality images, and geolocated pictures, we compare this data with the original design drawings. During this process, we identified a deviation: some of the basement walls were executed with different thicknesses compared to what was planned in the initial design documents. This early detection is crucial to neutralize problems in other phases of the project that would involve a high economic cost, such as the reorganization of the electrical installation.

The interesting thing is to have the possibility of comparing the current state with the planned state in real time to redirect construction times and processes, identifying deviations and possible errors at an early stage of the project. Professionals in the construction industry are aware of the importance of integrating advanced technologies such as the SUMMIT-XL that reliably automate preventive work in progress and quality reports.

A clear barrier in a construction environment is soil difficulties such as unevenness or holes. To be honest, none of the robotic solutions available on the market is valid for all scenarios and environments, that would be utopian. I think the important thing is to find a mobile robot that can operate in as many scenarios as possible, so that it is a truly profitable investment. At Robotnik we have worked a lot on both software and hardware regarding the mobility and efficient movement of the robot. Improving location and navigation allows us to minimize the obstacles that the variability of the terrain can generate.

The SUMMIT-XL is a truly versatile product for extensive building infrastructures, especially in non-residential outdoor environments such as office blocks or even public construction sites. Another challenge in this sector lies in the diversity of parties involved within a project, which are often not intrinsically related to each other and therefore lack a shared workflow.

The coordination of all these parts in a single working model represents a significant difficulty. The lack of seamless integration and collaboration between different project components can affect efficiency and consistency in the implementation of robotic technology, complicating the synchronization of processes and obtaining consistent data. Overcoming these challenges requires a comprehensive approach that addresses both the technical constraints of the physical environment and the need for integration and coordination between the various parts of the project, establishing collaborative workflows to maximize the benefits of technology in complex and multifaceted projects