Recent developments in robotics

Trends and recent developments in robotics that have marked this ending 2022.This article compiles the points that you…

What is a cobot and its benefits?

What is the meaning of ‘cobot’? What is a collaborative robot? What are the benefits of a cobot? These…

What is fleet management in robotics?

Within the Industry 4.0 context, it’s common to see a factory with more than one autonomous mobile robot (AMR)…

Robots for inspection and maintenance tasks

Inspection and maintenance tasks are a fundamental part of many industrial sectors: deteriorated infrastructures,…

Success case of Robotnik and its RB-KAIROS+ in a Netherlands company

AER publishes in its 2021 yearbook the success story of Robotnik and its RB-KAIROS+ in a gear production company.…

The 11 most frequently asked questions about autonomous mobile robotics

Robotnik is a leader in autonomous and collaborative mobile robotics. Here you can read some frequently asked…

The spanish Vice-president Nadia Calviño visits Valencia to learn first-hand about the Pilotos 5G project

Valencia has been the location to show the advances in 5G technology within the Pilotos 5G project, in which Robotnik,…

What is an Autonomous Mobile Robot (AMR)? What Robotnik AMR brings to your business

Introduction to autonomous mobile robots and what you should consider before choosing. Robotnik’s mobile…

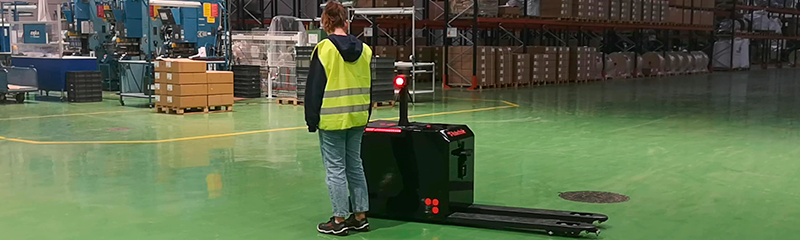

Mobile robots and safety: the experience of Robotnik in HR-RECYCLER project

Collaborative robots have come front and center on the international stage as they’ve become widespread in Industry…

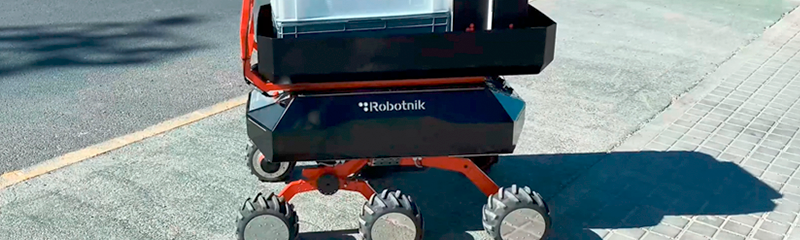

RB-VOGUI, a collaborative robot for outdoor transport in industry

The Eurecat technology center and Robotnik Automation have developed the RB-VOGUI, a highly modular, autonomous and…